Exploring Leading Manufacturers of Metal Roof Production Machinery for Your Construction Needs

An Overview of Metal Roof Machine Factories

In recent years, the construction industry has seen a significant shift towards the use of metal roofing materials due to their durability, energy efficiency, and aesthetic appeal. As a result, metal roof machine factories have emerged as critical players in the manufacturing landscape, providing advanced machinery to produce high-quality metal roofing panels. This article explores the role of these factories, the technology they employ, and the benefits they bring to both manufacturers and consumers.

The Role of Metal Roof Machine Factories

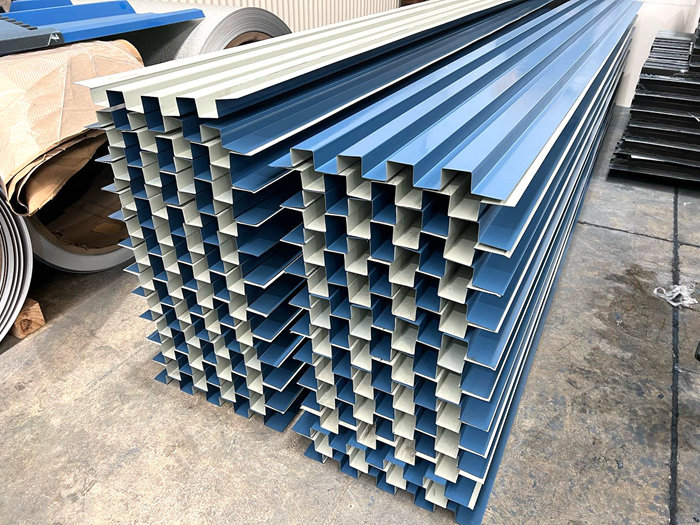

Metal roof machine factories specialize in manufacturing equipment that enables the production of metal roofing materials. These machines are designed to roll-form sheet metal into various shapes, allowing manufacturers to create panels that meet specific design and structural requirements. Common machinery includes roll formers, shears, and cutters, which are essential for producing a range of roofing products, from standing seam panels to corrugated sheets.

The increasing demand for metal roofs has prompted these factories to innovate continuously, leading to the development of automated solutions that enhance efficiency and reduce labor costs. By using advanced technology, such as Computer Numerical Control (CNC) systems, manufacturers can produce high volumes of roofing materials with precise dimensions, ensuring compatibility with standard construction practices.

Advanced Technology

The machinery produced by metal roof machine factories is often equipped with the latest technology to facilitate seamless production processes. For instance, many machines incorporate real-time monitoring systems that allow operators to track performance metrics and make adjustments on the fly. This not only improves the overall quality of the produced panels but also minimizes waste—a crucial consideration in today’s sustainable construction environment.

metal roof machine factories

Furthermore, some factories are adopting Industry 4.0 principles, integrating IoT (Internet of Things) devices into their machinery. This enables data collection and remote monitoring, allowing manufacturers to manage their production lines more effectively and respond swiftly to market demands. Such tech advancements not only save time but also reduce operational costs, making it a smart investment for manufacturers.

Environmental Benefits

Metal roofs are known for their energy efficiency, reflecting solar heat and thus reducing cooling costs during hot months. When paired with the right manufacturing machines, these roofs can also be designed to incorporate insulation materials, further enhancing their energy-saving capabilities. Metal roof machine factories are increasingly focusing on producing sustainable products that contribute to green building initiatives.

Moreover, the machinery used in these factories is often designed to minimize material waste. Innovative cutting techniques and optimized material usage contribute to an environmentally-friendly production process. As consumers become more conscious of their environmental footprint, the role of metal roof machine factories in producing sustainable roofing solutions becomes increasingly crucial.

Conclusion

In conclusion, metal roof machine factories play an indispensable role in the construction industry by providing the machinery required to produce high-quality metal roofing materials. With the incorporation of advanced technology and a focus on sustainability, these factories are positioned to meet the growing demand for metal roofs effectively. As the trend towards energy-efficient and durable building materials continues, the importance of metal roof machine factories will only increase, ensuring that they remain at the forefront of roofing innovations for years to come.