Efficient Z Channel Steel Roll Forming Equipment for Versatile Construction Applications

Understanding the Z Channel Steel Roll Forming Machine

In the realm of construction and manufacturing, the significance of steel structures cannot be overstated. Among various products manufactured from steel, the Z channel is particularly valued for its versatility and strength. To manufacture this essential material efficiently, the Z Channel Steel Roll Forming Machine plays a pivotal role. In this article, we will explore the mechanics, benefits, and applications of this innovative machine.

What is a Z Channel?

Before diving into the workings of the roll forming machine, it is essential to understand what a Z channel is. A Z channel is a type of steel profile that is shaped like the letter Z. This configuration offers certain advantages such as high strength-to-weight ratio and efficient load distribution, making it ideal for various construction applications. Typical uses include roofing supports, wall bracing, and frameworks for industrial buildings.

How Does a Z Channel Steel Roll Forming Machine Work?

The Z Channel Steel Roll Forming Machine operates on a continuous process that transforms steel coils into Z channels. The primary steps involved in this process include

1. Feeding The raw material, usually in the form of a steel coil, is fed into the machine. 2. Roll Forming As the coil is drawn through a series of rollers, it is progressively shaped into the desired Z channel profile. Each roller is precisely engineered to bend the steel at specific angles, gradually forming the Z shape.

3. Cutting After the roll forming process, the continuous steel strip is cut to the specified lengths. This is often accomplished using a hydraulic or mechanical cutting system that ensures precision and efficiency.

4. Punching and Notching In some cases, additional features such as holes or notches may be required for fitting or application purposes. The machine can be equipped with punching units to meet these specifications.

5. Finishing Finally, the produced Z channels can undergo surface treatments like galvanization or painting for enhanced durability and corrosion resistance.

Benefits of Using a Z Channel Steel Roll Forming Machine

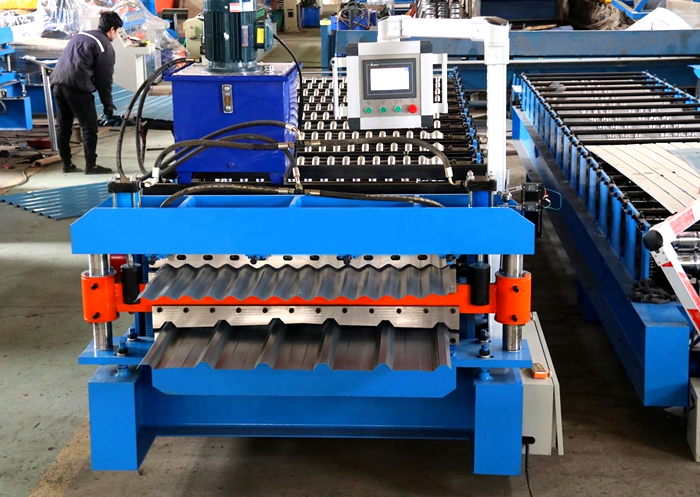

z channel steel roll forming machine

Investing in a Z Channel Steel Roll Forming Machine comes with several benefits

1. High Efficiency The roll forming process is highly efficient, enabling the production of large quantities of Z channels in a short period.

2. Consistency and Precision This machine provides uniform products with minimal deviation, which is crucial for construction applications where structural integrity is paramount.

3. Cost-Effectiveness By streamlining the production process, these machines can reduce both labor and material costs, ultimately improving profitability.

4. Customization Modern machines can be easily adjusted to produce various sizes and thicknesses of Z channels, allowing manufacturers to cater to diverse customer needs.

5. Automation Many Z channel roll forming machines are equipped with advanced automation features, reducing the need for manual intervention and enhancing safety.

Applications of Z Channels

Z channels are versatile components used in various applications. They are frequently utilized in

- Structural applications Providing support in buildings and warehouses. - Mechanical and electrical frameworks Serving as brackets or supports for equipment. - Roofing applications Supporting roof structures and cladding.

Conclusion

The Z Channel Steel Roll Forming Machine is an invaluable tool in the steel manufacturing industry. Its efficiency, precision, and ability to produce customized products make it a preferred choice for manufacturers aiming to meet the growing demands of construction and engineering projects. As technology continues to advance, these machines will likely become even more sophisticated, further enhancing their capabilities and the quality of the Z channels produced. Whether for building frameworks or industrial applications, the importance of Z channels—and the machines that create them—remains undeniable.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025