Efficient Roof Roll Forming Machine Production Line for High-Quality Metal Roofing Solutions

The Role of Roof Roll Forming Machine Factories in Modern Construction

In today's fast-paced construction industry, efficiency and precision are paramount. The roof roll forming machine has emerged as a pivotal technology that transforms the way roofing materials are produced. Various factories specializing in roof roll forming machines play an essential role in manufacturing these advanced devices, enabling construction companies to enhance their operations significantly.

Understanding Roof Roll Forming Machines

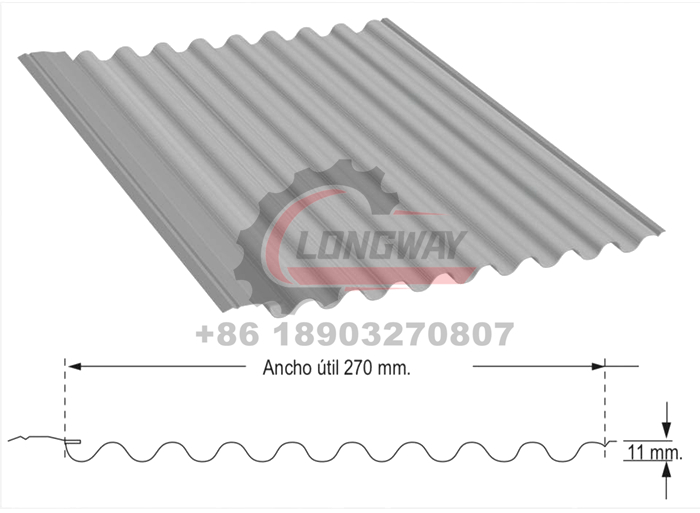

Roof roll forming machines are specialized equipment designed to create metal roofing panels from flat sheets of metal. This process involves feeding sheets of metal into the machine, where they are shaped and cut into specific profiles through a series of rollers and dies. These machines can produce a wide variety of roofing materials, including standing seam panels, corrugated sheets, and tile-like profiles, ensuring adaptability to various architectural styles and structural requirements.

Importance of Quality Manufacturing

The quality of roofing materials directly impacts the durability, aesthetics, and overall performance of a building. Therefore, factories that specialize in roof roll forming machines prioritize high standards in their manufacturing processes. Utilizing advanced technology, such as computer numerical control (CNC) systems, ensures that every panel produced is accurate and consistent. This precision minimizes waste and maximizes efficiency in both the production process and the eventual use of the roofing materials.

Customization and Flexibility

roof roll forming machine factory

One of the significant advantages of roof roll forming machine factories is their ability to offer customized solutions. Each construction project has unique requirements, from dimensions to specific design elements. Many manufacturers now provide bespoke machines tailored to individual needs, allowing for the production of custom profiles that meet specific architectural standards. This flexibility not only enhances creativity in design but also empowers builders to offer unique solutions to their clients.

Enhancing Efficiency and Reducing Labor Costs

The automation provided by roof roll forming machines significantly enhances manufacturing efficiency. These machines can operate at high speeds, producing large volumes of roofing materials in a short period. This capability not only accelerates the production timeline but also reduces labor costs, as fewer workers are needed to manage the manufacturing process. Consequently, companies can allocate resources more effectively and focus on other critical aspects of construction projects.

Sustainability Considerations

As the construction industry increasingly shifts toward sustainable practices, roof roll forming machine factories are also adapting to minimize their environmental impact. Many manufacturers are now utilizing recycled materials in their production processes and designing machines that reduce energy consumption. Additionally, metal roofing is known for its longevity and recyclability, making it a sustainable choice for construction projects. By providing efficient and eco-friendly solutions, these factories are contributing to a more sustainable future in building design and construction.

Conclusion

In conclusion, roof roll forming machine factories play a vital role in the modern construction landscape. By producing high-quality, customizable roofing materials efficiently and sustainably, they enable builders to meet the demands of a dynamic market. As technology continues to evolve, these factories will likely remain at the forefront of innovation, driving advancements in roofing solutions and contributing to the overarching goal of creating stronger, more resilient buildings. The partnership between construction firms and roof roll forming machine manufacturers symbolizes a collaborative effort towards achieving excellence in the field of construction.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025