Efficient Roll Forming Machines for Durable Roofing Sheet Production and Customization Solutions

Roofing Sheets Roll Forming Machine Transforming Construction with Efficiency and Precision

In the ever-evolving construction industry, efficiency, durability, and cost-effectiveness are paramount. One of the notable innovations that contribute to these factors is the roofing sheets roll forming machine. This advanced machinery is designed to produce high-quality roofing sheets in various shapes and sizes, catering to the diverse needs of the construction sector.

What is a Roofing Sheets Roll Forming Machine?

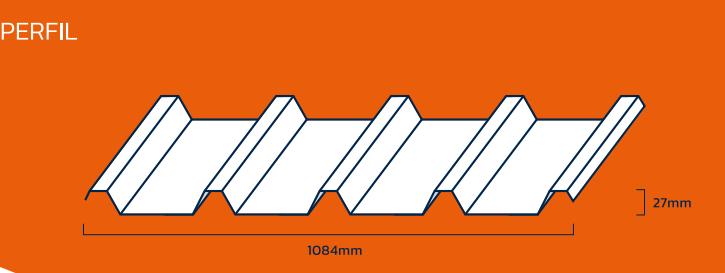

A roofing sheets roll forming machine is a type of industrial equipment that processes metal sheets into various roofing profiles through a continuous forming process. The machine utilizes a series of rollers to shape flat metal sheets—typically steel or aluminum—into desired configurations, such as corrugated, trapezoidal, or ribbed profiles. This method ensures that the resulting roofing materials are not only structurally sound but also visually appealing.

Key Features and Benefits

1. High Production Efficiency One of the most significant advantages of using a roll forming machine is its ability to produce roofing sheets at high speeds. These machines can operate continuously, which drastically reduces production time compared to traditional roofing manufacturing methods. This efficiency is particularly beneficial for large-scale construction projects where time is of the essence.

roofing sheets roll forming machine

2. Precision and Consistency Roll forming equipment is engineered to deliver precise and consistent results. The use of computer numerical control (CNC) technology allows for accurate adjustments during the forming process. As a result, manufacturers can achieve uniformity across batches, ensuring that each roofing sheet meets specific quality standards. This precision minimizes material waste and enhances overall project quality.

3. Versatility Roofing sheets roll forming machines can be designed to produce a variety of profiles, catering to different architectural styles and building requirements. Whether it’s for residential homes, commercial buildings, or industrial structures, these machines can adapt to produce sheets that meet diverse aesthetic and functional needs.

4. Durability and Strength The materials used in conjunction with roofing sheets roll forming machines, such as galvanized steel or stainless steel, contribute to the long-lasting nature of the roofing products. These materials are resistant to corrosion, extreme weather conditions, and physical wear, making them ideal for various applications. As a result, structures outfitted with roll-formed roofing sheets can enjoy extended lifespans with minimal maintenance.

5. Cost-Effectiveness The initial investment in a roofing sheets roll forming machine may be significant; however, the long-term savings can be substantial. By reducing labor costs, minimizing material waste, and increasing production speed, manufacturers can improve their profit margins. Additionally, the durability of the roofing sheets reduces the need for frequent repairs or replacements, further enhancing cost savings for building owners.

Conclusion

As the demand for robust and efficient construction materials continues to rise, the roofing sheets roll forming machine stands out as a revolutionary solution in the industry. With its ability to produce high-quality, durable roofing sheets quickly and economically, this machinery offers significant advantages to manufacturers and builders alike. Whether for residential or commercial projects, the adoption of roll forming technology signifies a commitment to quality and efficiency in modern construction practices. As technological advancements continue to unfold, we can expect further innovations in roofing solutions, paving the way for smarter building methods in the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025