Efficient Production of Corrugated Roofing Sheets Using Advanced Roll Forming Machinery Solutions

The Role of Corrugated Roof Sheet Roll Forming Machines in Modern Construction

In the realm of modern construction, the demand for sturdy yet lightweight roofing materials has surged. Among the various options available, corrugated roof sheets have gained significant popularity due to their durability, aesthetic appeal, and economic efficiency. At the heart of this production process lies the corrugated roof sheet roll forming machine, a technological marvel that enhances efficiency and quality in manufacturing.

Understanding Corrugated Roof Sheet Roll Forming Machines

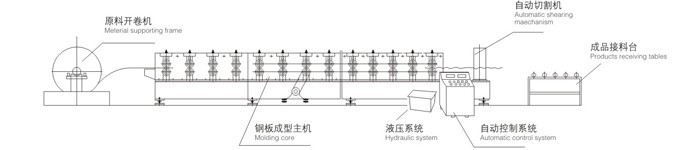

A corrugated roof sheet roll forming machine is designed to create sheets with a series of ridges and grooves, enhancing their structural strength while reducing weight. The process begins with feeding a continuous coil of sheet metal, often galvanized steel or aluminum, into the machine. Through a series of rollers, the machine progressively shapes the metal into the desired corrugated profile. The final product is not only light but also capable of withstanding harsh weather conditions, making it an ideal choice for roofing in various applications, from residential buildings to large industrial warehouses.

The Advantages of Using Roll Forming Machines

1. Customizability One of the key benefits of roll forming machines is their ability to produce roofing sheets in various profiles, thicknesses, and lengths. This customization allows builders to meet specific design requirements while ensuring that the sheets can fit seamlessly into any architectural style.

2. Efficiency and Speed Roll forming machines are remarkably efficient, capable of producing large quantities of sheets in a short amount of time. This efficiency translates to lower labor costs and quicker project turnaround times, which are critical in the fast-paced construction industry.

3. Material Optimization The precision of the roll forming process minimizes waste. As the machine molds the metal sheets, it ensures that each piece is cut to the exact specifications needed, reducing scrap material and saving costs.

corrugated roof sheet roll forming machine

4. Durability and Performance Corrugated sheets produced by roll forming machines are not only aesthetically pleasing but also designed to last. The corrugated shape enhances the strength of the sheets, providing superior resistance to bending, snow loads, and other environmental stresses. Additionally, coatings can be applied during the manufacturing process to enhance corrosion resistance and UV protection.

5. Eco-Friendly Production Many manufacturers are incorporating eco-friendly practices in their production processes. Roll forming machines can efficiently use recycled materials, further promoting sustainability in construction.

Applications of Corrugated Roof Sheets

The applications for corrugated roof sheets are extensive. They are widely utilized in residential, agricultural, and commercial projects. For instance, in agricultural settings, these sheets are often used for barns and storage facilities due to their weather-resistant properties. In urban environments, they form the roofs of both residential and commercial buildings, contributing to modern architectural designs.

Moreover, corrugated roofing is an excellent choice for temporary structures, such as site huts and shelters, because of its lightweight nature and ease of installation. Its versatility makes it an invaluable asset in various sectors, including construction, manufacturing, and agriculture.

Conclusion

As the construction industry evolves, the importance of innovative solutions like the corrugated roof sheet roll forming machine cannot be overstated. These machines not only enhance production capabilities but also ensure that builders can meet the growing demands for durable, efficient, and sustainable building materials. The future of roofing is undoubtedly linked with advanced manufacturing technologies, and roll forming is at the forefront of this revolution, paving the way for sturdy structures that stand the test of time.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025