Durable and Efficient Corrugated Roof Roll Forming Equipment for High-Quality Roofing Solutions

The Corrugated Roof Roll Forming Machine A Comprehensive Overview

In the construction industry, durability and efficiency are paramount. One of the essential components that contribute to these factors is the roofing system. Among various roofing options, corrugated roofs have gained immense popularity due to their strength, lightweight nature, and ease of installation. The process of manufacturing corrugated roofing sheets has been revolutionized by advanced technology, particularly through the use of the corrugated roof roll forming machine.

What is a Corrugated Roof Roll Forming Machine?

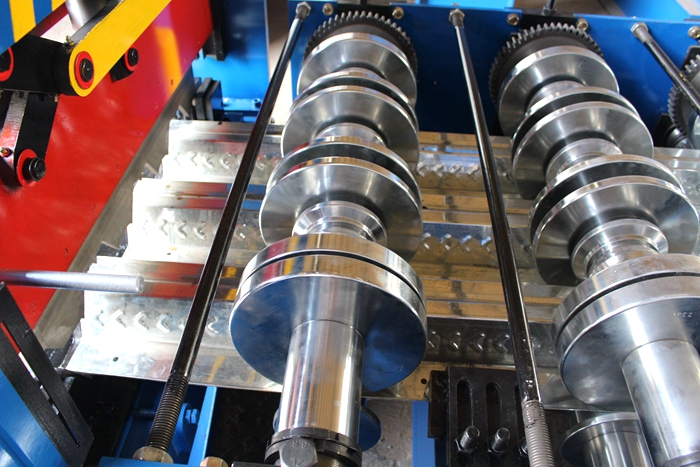

A corrugated roof roll forming machine is a specialized piece of equipment designed to create corrugated sheets from metal coils. The machine works by passing metal sheets through a series of rollers that shape the metal into the desired corrugated pattern. This process not only enhances the aesthetic appeal of the roof but also significantly improves the structural integrity of the material, making it an ideal choice for various applications, including residential, commercial, and industrial buildings.

Key Features of the Machine

1. High Efficiency Modern roll forming machines operate at high speeds, allowing manufacturers to produce corrugated sheets in large quantities with minimal manual intervention. This efficiency translates into cost savings and faster project completion times.

2. Precision Engineering The machines are designed with precision in mind. Advanced technology ensures that the corrugated profiles are uniform and meet specific industry standards. This accuracy is crucial for ensuring proper installation and long-term performance.

3. Versatility A corrugated roof roll forming machine can be customized to produce different shapes, sizes, and thicknesses of sheets. This versatility makes it suitable for various roofing applications, catering to the diverse needs of the construction industry.

4. Durability The materials used in these machines are robust and designed to withstand heavy usage. This ensures that the machinery has a long operational life with minimal maintenance, making it a worthwhile investment for manufacturers.

corrugated roof roll forming machine

5. Automated Systems Many modern machines come equipped with automated controls and sensors that monitor production processes in real-time. This automation improves accuracy and reduces human error, resulting in higher-quality products.

Advantages of Using Corrugated Roof Roll Forming Machines

The advantages of using corrugated roof roll forming machines extend beyond efficiency and precision. Some notable benefits include

- Cost-Effectiveness By producing roofing sheets quickly and without excessive waste, companies can save on material costs and labor expenses.

- Sustainability The process of roll forming can minimize material wastage, and many machines are compatible with recyclable materials, supporting eco-friendly practices in construction.

- Enhanced Strength Corrugated roofing is inherently stronger than flat sheets due to its shape, which provides excellent resistance to wind and other environmental factors.

- Aesthetic Appeal The corrugated design not only offers functionality but also adds an attractive element to the building, making it a popular choice among architects and builders.

Conclusion

As the construction industry continues to evolve, the importance of efficient and robust manufacturing processes cannot be overstated. The corrugated roof roll forming machine stands out as a critical tool for producing high-quality roofing materials that meet the demands of modern construction. With its combination of efficiency, precision, and versatility, it has become an invaluable asset for manufacturers aiming to deliver durable and aesthetically pleasing roofing solutions. As we look to the future, advancements in machine technology will undoubtedly continue to enhance the quality and efficiency of corrugated roofing production, benefiting builders and homeowners alike.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025