Manufacturer of Roll Forming Machines for Drywall Stud Production

The Importance of Drywall Stud Roll Forming Machines in Construction

In the fast-paced world of construction, efficiency and precision are paramount. One of the essential components that contribute to both is the use of drywall stud roll forming machines. These machines have revolutionized the way we build structures, particularly in creating metal studs for drywall applications. As the demand for lightweight and durable building materials increases, the role of the drywall stud roll forming machine manufacturer becomes increasingly significant.

What Are Drywall Stud Roll Forming Machines?

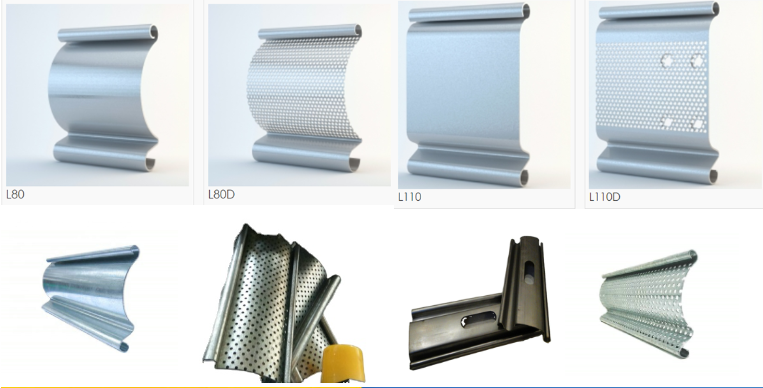

Drywall stud roll forming machines are specialized equipment designed to produce metal studs used in drywall systems. These machines function by feeding metal coil through a series of rollers that shape it into studs of various sizes and profiles. The final product is essential in the construction of walls and ceilings, providing the necessary framework for drywall installation.

Advantages of Using Drywall Stud Roll Forming Machines

1. Efficiency One of the primary benefits of these machines is their ability to produce large volumes of studs quickly. This efficiency is crucial in meeting tight construction timelines and managing costs. A well-designed roll forming line can operate continuously, significantly increasing production rates.

2. Cost-Effectiveness By automating the production of metal studs, manufacturers can reduce labor costs and minimize material waste. The precision of the roll forming process ensures that each stud is uniform, which reduces the risk of errors and rework.

3. Quality Control Manufacturers of drywall stud roll forming machines emphasize the importance of quality in their production processes. The machines allow for precise measurements and consistent production standards, which helps ensure that the studs meet industry specifications and building codes.

drywall stud roll forming machine manufacturer

4. Versatility These machines can be designed to produce various profiles and thicknesses of studs, catering to different construction needs. This versatility means that manufacturers can adapt their production lines to meet specific project requirements, from residential to commercial buildings.

5. Sustainability In an age where sustainability is a critical concern, drywall stud roll forming machines enable manufacturers to utilize recycled materials. Metal studs can be made from recycled steel, reducing the overall carbon footprint of construction projects.

The Role of Manufacturers

The expertise and technological advancements brought forth by drywall stud roll forming machine manufacturers play a crucial role in the industry. These manufacturers are not only responsible for producing the machines but also for providing support and training to their clients. They understand the intricacies of roll forming technology and continuously innovate to improve their products.

Moreover, a manufacturer’s reputation hinges on the durability and reliability of their machines. As construction projects typically involve significant investment, builders must trust that their equipment can perform consistently under demanding conditions. Manufacturers must also stay updated with the latest trends and developments in building materials and techniques to remain competitive.

Conclusion

In conclusion, drywall stud roll forming machines are an integral part of the construction industry, streamlining the process of creating essential components for drywall installations. The advantages of using these machines—from efficiency and cost-effectiveness to quality and sustainability—cannot be overstated. As the industry continues to evolve, the partnership between builders and drywall stud roll forming machine manufacturers will be essential in driving innovation and meeting the changing demands of construction. Investing in high-quality machinery and building a strong relationship with a reputable manufacturer will ultimately lead to successful project outcomes and contribute to the overall advancement of the construction field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025