drywall stud roll forming machine factories

Understanding Drywall Stud Roll Forming Machine Factories

The construction industry has witnessed significant advancements over the years, particularly in the machinery utilized for manufacturing building materials. One of the critical components in many construction projects is drywall, which is typically supported by metal or wooden stud frames. To streamline the production of these essential components, drywall stud roll forming machines have emerged as vital equipment in factories. This article will delve into the role of drywall stud roll forming machine factories and their significance in modern construction.

The Basics of Drywall Stud Roll Forming Machines

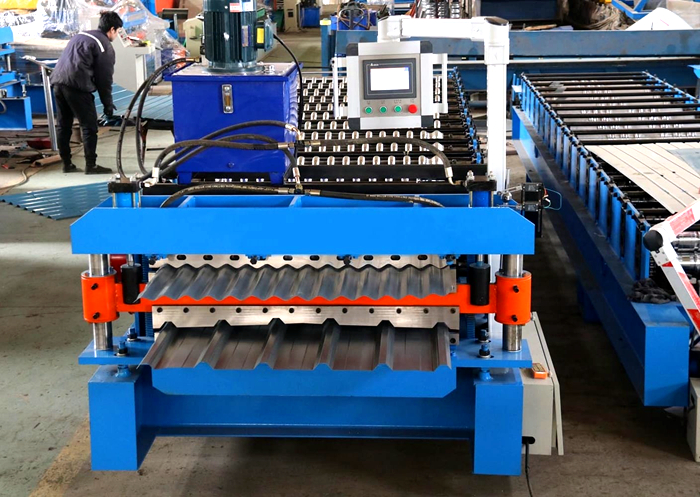

Drywall stud roll forming machines are specialized equipment designed to produce metal studs used in drywall framing. These studs are usually made from galvanized steel or other metal alloys, providing durability and strength to the wall structures. The roll forming process involves feeding a flat metal sheet through a series of rollers, gradually shaping it into the desired profile that can then be cut to specified lengths.

The efficiency of these machines allows for the mass production of consistently shaped studs, which significantly accelerates construction timelines

. Moreover, the precision of roll forming minimizes waste, making it a cost-effective production method compared to traditional fabrication techniques.The Importance of Factories

Factories that specialize in the production of drywall stud roll forming machines play a crucial role in the supply chain of the construction industry. These facilities are responsible for not only manufacturing the machines themselves but also for ensuring that they meet the stringent quality control standards required in the industry.

drywall stud roll forming machine factories

1. Innovative Technology Modern drywall stud roll forming machine factories invest in advanced technology and automation. By employing cutting-edge software and machinery, they enhance production efficiency and accuracy. This innovation allows for rapid adjustments to machine settings, accommodating different stud sizes and profiles, thus catering to diverse project requirements.

2. Customization Every construction project has unique demands, and drywall stud roll forming machine factories are adept at providing customized solutions. Clients can specify the dimensions, materials, and production speed, ensuring that the final output aligns perfectly with their project needs. This level of customization fosters stronger relationships between manufacturers and builders, ultimately leading to better project outcomes.

3. Training and Support Beyond production, these factories often provide training and support for their machinery. Many companies recognize that purchasing advanced equipment is just the first step; operators need to be trained on how to optimize the machines for maximum output and efficiency. Comprehensive training programs help enhance worker productivity and reduce downtime, a critical factor in construction.

4. Sustainability There is an increasing focus on sustainability in the construction industry. Factories are adopting practices that minimize their environmental impact, such as using recycled materials for production and improving energy efficiency in manufacturing processes. By prioritizing eco-friendly practices, they contribute to the broader movement towards sustainable building solutions.

Conclusion

The role of drywall stud roll forming machine factories is indispensable in the construction sector. As demand for efficient and high-quality building materials grows, these factories are poised to meet the challenge. Through innovation, customization, training, and sustainability efforts, they not only enhance the manufacturing process but also drive the industry towards a more efficient and responsible future. As technology continues to evolve, it is likely that these factories will play an even more significant role in the development of construction materials, ensuring that builders have access to the best resources to create durable and safe structures.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025