drip edge roll forming machine factories

Drip Edge Roll Forming Machine Factories Revolutionizing Construction Efficiency

In the world of construction, efficiency and precision are paramount. As the industry continues to evolve, innovative machinery plays a critical role in streamlining production processes. Among these advancements, the drip edge roll forming machine stands out as a vital tool for manufacturers and builders alike.

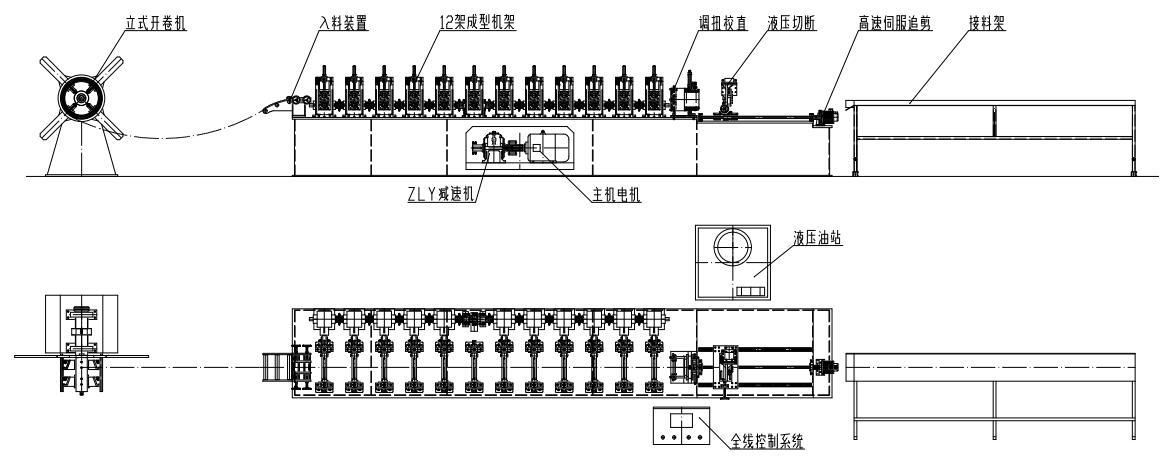

A drip edge is an essential component in roofing construction, designed to direct water away from the fascia and help prevent water damage. The roll forming machine specializes in creating drip edges by continuously feeding metal coils through a series of rollers that shape the material into the desired profile. This machine not only enhances the efficiency of production but also improves the consistency and quality of the final product.

Benefits of Drip Edge Roll Forming Machines

1. Cost Efficiency Factories that utilize drip edge roll forming machines significantly reduce labor costs. Automation minimizes the need for manual labor, allowing for fewer workers to oversee production. Moreover, the ability to produce drip edges on-site reduces waste and transportation costs, further optimizing overall expenses.

2. Precision and Quality Control Modern roll forming machines come equipped with advanced technology that ensures precise dimensions and high-quality finishes. This precision leads to fewer defects and a reduced need for rework, ultimately saving time and resources. Factories can maintain strict quality control standards, meeting the demands of clients and regulatory requirements.

drip edge roll forming machine factories

3. Versatility Drip edge roll forming machines offer flexibility in design. Manufacturers can easily switch between different profiles and sizes, allowing them to cater to various customer needs without investing in new machinery. This adaptability is particularly beneficial in an industry where customizations are frequently requested.

4. Increased Production Speed The high-speed capabilities of modern roll forming machines lead to enhanced production rates. Factories can produce large quantities of drip edges in a fraction of the time it would take using traditional methods. This increase in speed can lead to faster project completion times, positively impacting overall business agility.

5. Sustainability With the growing awareness of environmental issues, manufacturing processes must also prioritize sustainability. Drip edge roll forming machines can efficiently utilize materials, leading to less waste and a lower carbon footprint. Additionally, many manufacturers are turning to recycled metals, contributing to a more sustainable industry.

Conclusion

The rise of drip edge roll forming machine factories marks a significant advancement in the construction sector. By focusing on efficiency, precision, and versatility, these factories are well-equipped to meet the evolving demands of the market. As technology continues to improve, we can expect further innovations in manufacturing processes that enhance productivity while promoting sustainability.

In summary, embracing the benefits of drip edge roll forming machines not only equips manufacturers with the tools necessary for success but also sets a standard for quality and efficiency in the roofing component industry. As these machines become more prevalent, they will undoubtedly shape the future of construction, paving the way for smarter, more efficient building practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025