drip edge roll forming machine companies

The Role of Drip Edge Roll Forming Machine Companies in Building Construction

In the realm of modern construction, every tiny element plays a crucial role in ensuring the overall integrity and durability of a structure. Among these elements, drip edge is an often-overlooked component that serves a vital purpose in protecting a building from water-related damage. As builders and contractors seek efficient ways to manufacture this essential feature, drip edge roll forming machine companies have emerged as indispensable partners in the construction industry.

Understanding Drip Edge and Its Importance

Drip edge is a metal flashing installed along the edges of roofs. Its primary function is to direct water runoff away from the fascia and into the gutters, preventing water from seeping underneath the roofing material. This not only safeguards the roof but also protects the underlying structures from moisture, mold, and rot. Without a properly installed drip edge, a building’s longevity is significantly compromised, leading to costly repairs and potentially disastrous consequences.

The Rise of Roll Forming Technology

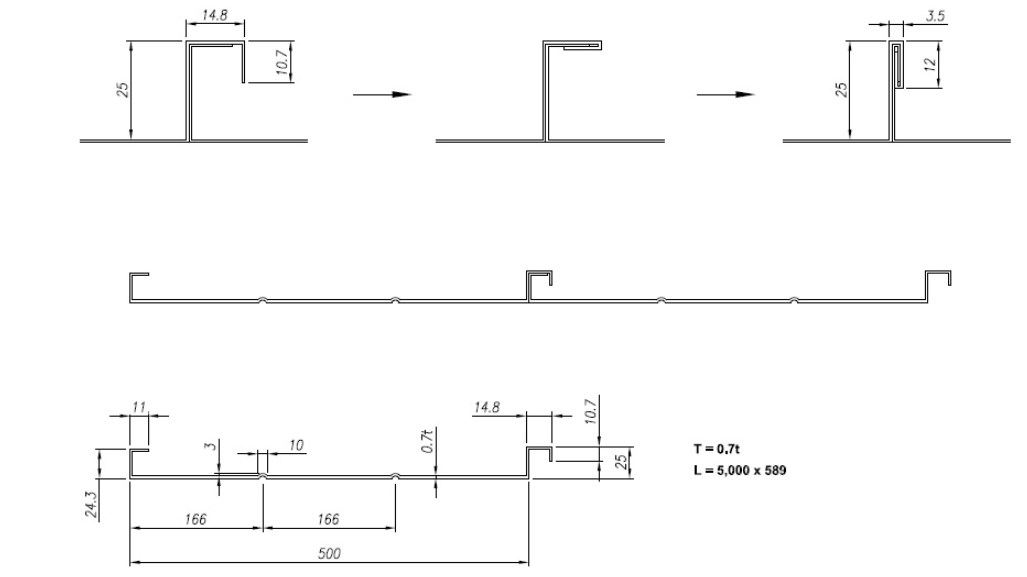

Roll forming is a manufacturing process that allows for the continuous shaping of metal sheets into desired profiles. This technique has gained popularity in various industries, particularly in roofing and construction, due to its efficiency in producing high volumes of custom shapes at a lower cost. Drip edge roll forming machines are specifically designed to create drip edge profiles quickly and accurately, catering to the demands of contractors who need reliable materials for their projects.

Features of Drip Edge Roll Forming Machines

Drip edge roll forming machines come equipped with various features that enhance their functionality. These machines typically include

1. Advanced Control Systems Modern roll forming machines use programmable logic controllers (PLCs) which allow for precise adjustments in production settings. This enables manufacturers to produce drip edges in different lengths, thicknesses, and profiles efficiently.

drip edge roll forming machine companies

3. Durability and Reliability Drip edge roll forming machines are built with robust materials to withstand continuous use in production environments. This durability ensures that the machinery can operate reliably over long periods.

4. Customization Options Companies can adjust the machines to create various drip edge profiles according to specific building codes and architectural designs. This customization capability is vital in meeting the diverse needs of different projects.

Companies Leading the Charge

Numerous companies specialize in producing drip edge roll forming machines, each offering unique advantages based on their technology and expertise. These companies often focus on continuous innovation, improving their machines' efficiency, ease of use, and output quality.

1. Market Leaders Some of the well-established names in the industry are known for their high-quality machines, customer service, and technological advancements. They typically offer training and support to ensure that clients can effectively operate and maintain the machinery.

2. Emerging Players New companies entering the market are often driven by the latest technological advancements, providing innovative solutions that cater to the evolving needs of the construction industry. These companies often focus on sustainability, offering machines that consume less energy and produce less waste.

The Future of Drip Edge Roll Forming

As the construction industry continues to embrace efficiency and sustainability, the demand for drip edge roll forming machines will likely grow. Advances in automation and smart technology may also play a substantial role in the future of these machines, allowing for even greater levels of customization and efficiency.

Conclusion

Drip edge roll forming machine companies play a pivotal role in the construction industry by providing essential tools that help ensure the durability and longevity of buildings. As builders increasingly recognize the importance of quality materials, these companies will continue to be key players in the narrative of modern construction. Investing in advanced roll forming technology not only enhances manufacturing efficiency but also contributes to the overall quality and safety of construction projects. As the industry evolves, these companies will remain at the forefront, shaping the future of building construction through innovation and precision.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025