Top Drip Edge Roll Forming Machine Manufacturers and Their Features

Understanding the Role of Drip Edge Roll Former Manufacturers

In the modern construction and roofing industry, the importance of effective water drainage cannot be overstated. Among the various components designed specifically for this purpose is the drip edge, which plays a crucial role in safeguarding the structural integrity of buildings. To meet the growing demand for high-quality drip edges, drip edge roll former manufacturers have emerged as key players in the production of these essential components.

What is a Drip Edge?

A drip edge is a metal flashing installed along the eaves and rakes of a roof. Its primary function is to direct water away from the fascia and into the gutter, preventing moisture damage to the roof structure and the underlying materials. Additionally, a properly installed drip edge can help to prevent issues such as ice damming in colder climates, where melting snow can refreeze and cause backups on the roof.

The Role of Drip Edge Roll Former Manufacturers

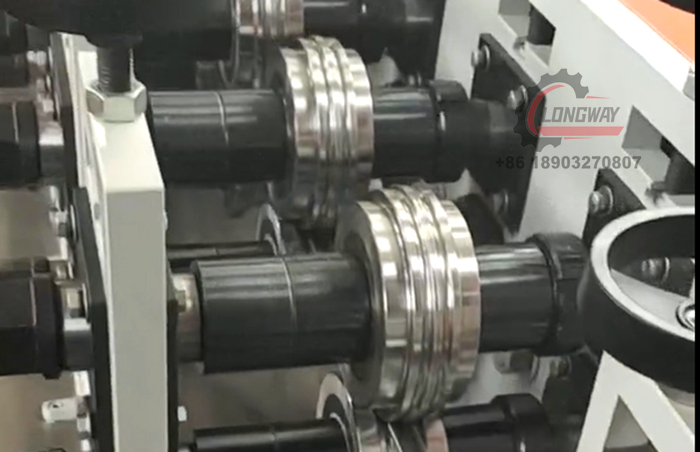

Drip edge roll former manufacturers specialize in producing the machines that create drip edges from metal coils. These machines, known as roll formers, transform flat metal stock into finished products through a series of rollers that shape the metal into the desired profile. The efficiency of these machines is crucial for manufacturers aiming to meet market demands while maintaining high-quality standards.

Roll forming offers several advantages in the production of drip edges. First, it enables the creation of long, continuous lengths of material, reducing waste and improving efficiency. Additionally, the process allows for precise control over the dimensions and shapes, ensuring that each piece meets the specifications required for effective installation.

Innovations in Drip Edge Production

drip edge roll former manufacturer

As the demand for drip edges has increased with the growth of the construction industry, so too has the technology used in roll forming machines. Modern manufacturers are incorporating advanced features such as computer numerical control (CNC) systems, which allow for more precise and versatile production processes. CNC technology facilitates quick changes to machine settings, enabling manufacturers to produce various drip edge profiles without extensive downtime.

Moreover, many manufacturers are now focusing on producing eco-friendly drip edges. By utilizing recycled metals and implementing sustainable manufacturing practices, these companies are contributing to the overarching goal of reducing the environmental impact of construction activities.

Quality Assurance and Standards

Quality control is a paramount consideration for drip edge roll former manufacturers. The performance of drip edges is directly linked to the quality of the materials used and the manufacturing processes employed. Manufacturers often adhere to industry standards, such as those set forth by the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), which govern the quality and performance characteristics of building materials.

Thorough testing of finished products ensures that they can withstand environmental challenges, such as extreme weather conditions. This includes resistance to corrosion, deformation, and deterioration over time. By employing rigorous quality assurance protocols, manufacturers can guarantee that their products will perform effectively over the long term.

Conclusion

In conclusion, drip edge roll former manufacturers play an essential role in the roofing and construction industries. By producing high-quality drip edges, they safeguard the integrity of buildings while also addressing environmental concerns through innovative manufacturing techniques. As technology continues to evolve, these manufacturers are poised to meet the increasing demands of the market, ensuring that effective water drainage solutions remain accessible to builders and homeowners alike. With their focus on quality, precision, and sustainability, drip edge roll former manufacturers are helping to shape the future of roofing solutions in an ever-changing construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025