drip edge roll former for sale manufacturers

Exploring Drip Edge Roll Formers A Guide for Buyers

In the ever-evolving construction and manufacturing industries, the importance of high-quality materials cannot be overstated. Among those crucial components, drip edges play a pivotal role in protecting roofs from water damage. As a result, the demand for drip edge roll formers has surged, leading many manufacturers to produce a variety of options for sale. This article explores the significance of drip edge roll formers and provides insights for potential buyers looking to invest in this essential machinery.

What is a Drip Edge Roll Former?

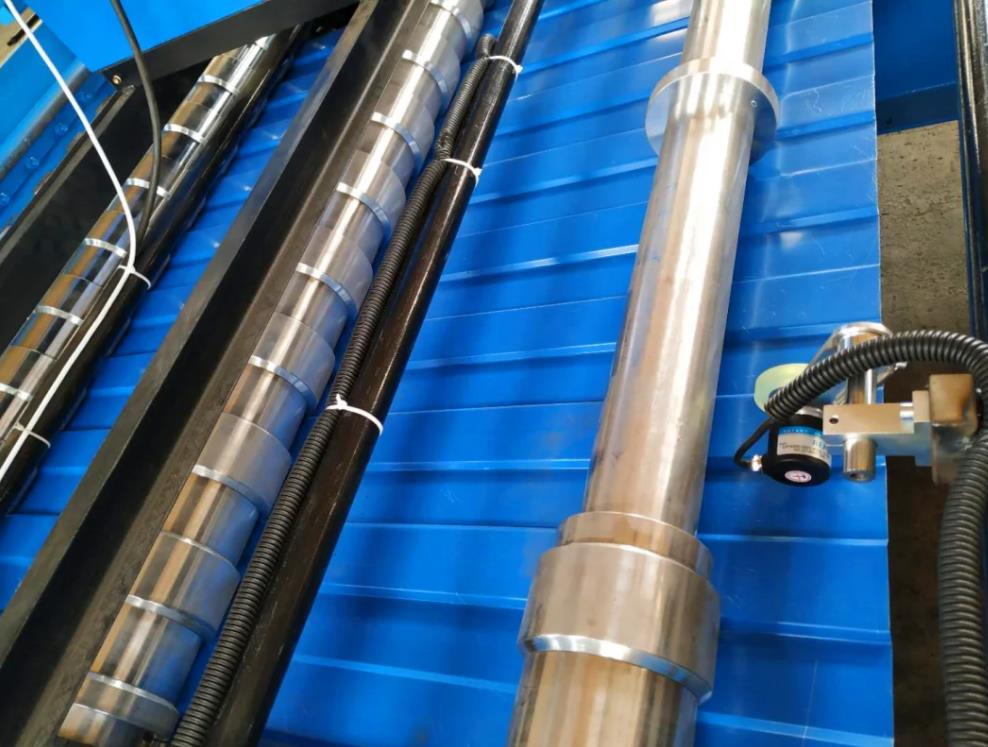

A drip edge roll former is a specialized machine designed to continuously produce drip edges, which are metal strips installed along the edges of a roof to direct water away from the fascia and into the gutters. These machines can create various profiles and dimensions, accommodating different construction needs and aesthetic preferences. The roll-forming process involves feeding a coil of metal into the machine, which then shapes it into the desired profile through a series of rollers.

Importance of Drip Edges

Drip edges are not just aesthetic—they serve critical functional purposes. They help prevent water from seeping under shingles, reducing the risk of rotting wood and mold development. Furthermore, they enhance the overall durability of the roofing system, ensuring longevity and reducing repair costs. Given these factors, investing in a reliable drip edge roll former is essential for manufacturers focused on quality and efficiency.

Key Considerations When Buying a Drip Edge Roll Former

1. Quality of Construction When selecting a drip edge roll former, it is imperative to assess the build quality. Look for machines constructed from durable materials that can withstand prolonged use without compromising performance. High-quality rollers and components will lead to better product consistency and lower maintenance costs.

2. Production Capacity Determine your production needs. Different machines offer varying levels of output, so consider how quickly you need to produce drip edges to meet customer demands. A machine with a higher production capacity may be a worthwhile investment if you anticipate increased demand.

drip edge roll former for sale manufacturers

3. Flexibility The ability to produce various profiles and dimensions can give your business a competitive edge. A versatile drip edge roll former that can easily adjust settings for different products can save time and money in the long run.

4. Ease of Use User-friendly controls and interfaces can significantly reduce the learning curve for your employees. Consider machines with intuitive operation systems, which can help streamline the production process and minimize errors.

5. After-Sales Support and Warranty Reliable after-sales support can make a considerable difference, especially during the installation and maintenance phases. Ensure that manufacturers offer robust warranties and support services to help troubleshoot any potential issues that may arise.

6. Cost-effectiveness While it may be tempting to opt for the cheapest option, it's crucial to weigh the cost against the machine's features, durability, and performance. A slightly higher initial investment in a quality machine can yield significant savings over time through reduced maintenance and higher production efficiency.

Where to Find Manufacturers

With the rise in demand for drip edge roll formers, several manufacturers now offer these machines for sale. Online platforms, industry trade shows, and networking events are excellent ways to discover reputable manufacturers. It's also wise to seek recommendations from industry peers or consult forums dedicated to metalworking and manufacturing.

Conclusion

Investing in a drip edge roll former can be a game-changer for businesses in the construction and roofing industries. By understanding the significance of drip edges and what to consider when purchasing machinery, buyers can make informed decisions that enhance their production capabilities while ensuring high-quality outputs. In a market where quality and efficiency are paramount, selecting the right equipment can set a company apart from its competitors. With careful research and consideration, your investment in a drip edge roll former will pay off in durability, reliability, and ultimately, customer satisfaction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025