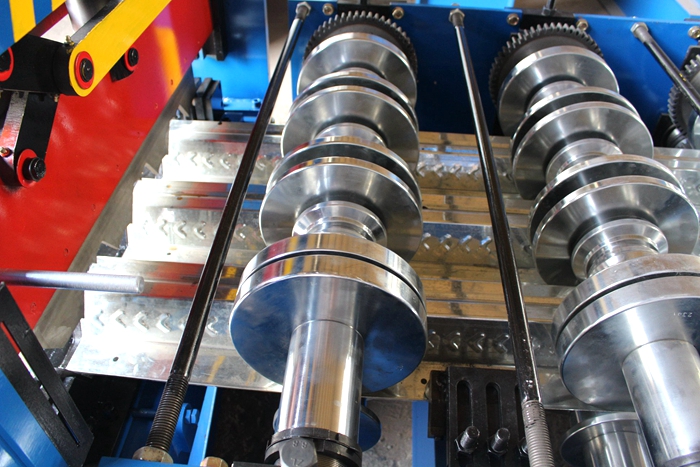

drip edge machine factory

The Rise of Drip Edge Machine Factories A Key Component in Modern Construction

In recent years, the construction industry has seen a significant transformation, with technology playing a pivotal role in enhancing efficiency and productivity. One of the unsung heroes of this evolution is the drip edge machine, a specialized piece of equipment that has become indispensable for roofing and construction professionals. This article explores the significance of drip edge machine factories and their impact on the industry.

Drip edges are essential components in roofing systems, designed to direct water away from the roof and prevent damage to the underlying structures. These metal strips are installed along the edges of roofs, ensuring that rainwater flows efficiently into gutters rather than seeping into the roofing materials or walls. As the demand for quality roofing materials grows, so does the need for reliable and efficient drip edge machines that can produce high-quality products.

The Rise of Drip Edge Machine Factories A Key Component in Modern Construction

One of the main advantages of modern drip edge machine factories is their ability to scale production. With the construction sector expanding rapidly, the need for quick turnaround times has never been more critical. Factories equipped with cutting-edge technology can produce large quantities of drip edges within tight deadlines, ensuring that projects stay on schedule. This efficiency not only benefits manufacturers but also enables contractors to meet customer demands without compromising quality.

drip edge machine factory

Furthermore, these factories prioritize sustainability in their production processes. By utilizing recyclable materials and minimizing waste, drip edge machine manufacturers contribute to a more environmentally friendly construction industry. As awareness of environmental issues increases, builders are increasingly seeking out suppliers that align with their sustainability goals, making eco-friendly practices a competitive advantage for drip edge machine factories.

The rise of automation in manufacturing has also played a significant role in the development of drip edge machine factories. Automated systems reduce the risk of human error and increase consistency in product quality. With features like computer-assisted design (CAD) and robotics, factories can produce drip edges with precision, allowing for tighter tolerances and enhanced performance.

Moreover, the globalization of the construction industry has led to an increased demand for drip edges across different regions. Drip edge machine factories are strategically positioned to serve local markets while being part of a global supply chain. This connectivity ensures that builders and contractors have access to the materials they need, regardless of their location, fostering collaboration and innovation within the industry.

In conclusion, drip edge machine factories are playing a crucial role in modern construction by supplying high-quality, efficient, and sustainable roofing solutions. As the industry continues to grow and evolve, these factories will remain at the heart of manufacturing innovation, driving progress and meeting the ever-changing demands of construction. With sustainability and automation leading the charge, the future of drip edge manufacturing holds great promise, ensuring that builders can protect their structures while adhering to contemporary standards of quality and environmental responsibility.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025