downspout forming machine manufacturer

Exploring the World of Downspout Forming Machine Manufacturers

In the realm of metal forming and fabrication, the downspout forming machine stands out as a crucial piece of equipment for manufacturers of rainwater management systems. This innovative machinery streamlines the production of downspouts, which are essential for directing rainwater from roofs to drainage systems and preventing potential damage to buildings and landscapes. As the demand for quality rainwater harvesting and drainage solutions rises, so does the importance of reliable downspout forming machine manufacturers.

Understanding Downspout Forming Machines

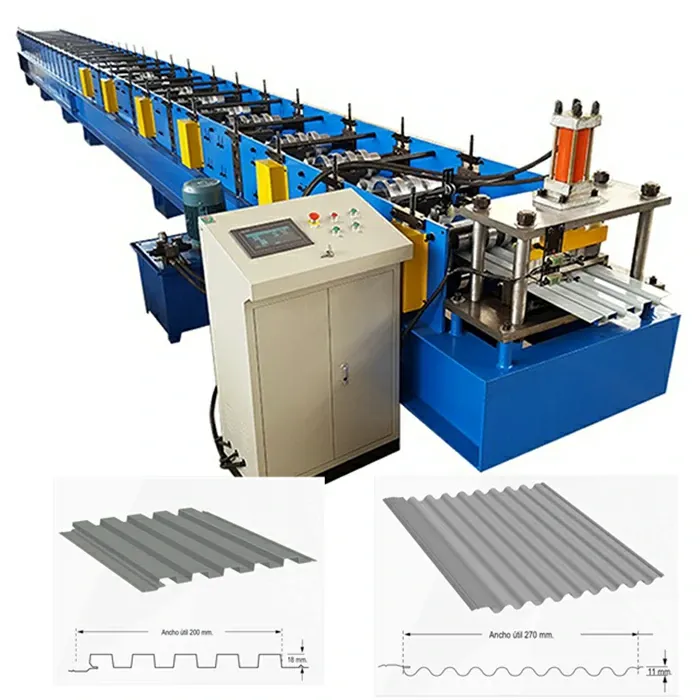

Downspout forming machines are specialized tools designed to create seamless, high-quality downspouts from metal sheets, typically aluminum, galvanized steel, or copper. These machines work by feeding large rolls of metal into the machine, where they undergo a series of processes, including cutting, bending, and shaping, to produce the final product. The results are uniform, durable downspouts that can withstand various weather conditions and enhance the aesthetic appeal of buildings.

The Benefits of Investing in a Downspout Forming Machine

For manufacturers, investing in a downspout forming machine can lead to numerous advantages

1. Efficiency and Speed Modern downspout forming machines are equipped with advanced technology that enables high-speed production without compromising on quality. This means that manufacturers can meet high demands with shorter lead times.

2. Precision and Consistency The automation of the forming process reduces the potential for human error, ensuring that each downspout produced is consistent in quality and dimensions. High precision is crucial, especially when fittings must be compatible with various gutter systems.

3. Cost-Effectiveness By streamlining the production process, manufacturers can lower their operational costs. Additionally, producing downspouts in-house eliminates the need for outsourcing, further reducing expenses and increasing profit margins.

4. Customization Options Many manufacturers require specific sizes, shapes, and colors for their downspouts to match architectural styles. A downspout forming machine can be easily adjusted to accommodate custom orders, providing manufacturers with greater flexibility to meet client needs.

The Role of Manufacturers

downspout forming machine manufacturer

Downspout forming machine manufacturers play an essential role in this industry. They are responsible for designing, engineering, and producing the machinery that other companies rely on to create their products. The best manufacturers focus on innovation, incorporating the latest technology and improving the efficacy and reliability of their machines.

Reputable downspout forming machine manufacturers also provide comprehensive support services, including installation, training, and ongoing maintenance. This support ensures that their clients can operate the machines efficiently and effectively, minimizing downtime and maximizing productivity.

Choosing the Right Manufacturer

When seeking a downspout forming machine, manufacturers should consider several important factors

1. Reputation Look for manufacturers with a proven track record of delivering high-quality machines. Reviews and testimonials from other businesses can offer valuable insights.

2. Technology and Features Investigate the specifications and technological features of the machines available. Advanced features may include digital controls, automatic feeding systems, and energy-efficient designs.

3. Customer Support A reliable manufacturer will provide excellent customer service, including installation assistance and technical support. This can be critical for resolving any operational issues that may arise.

4. Warranty and Maintenance Inquire about warranties and maintenance contracts. A good warranty can provide peace of mind, while proper maintenance ensures the longevity and optimal performance of the machinery.

Conclusion

The role of downspout forming machines and their manufacturers is integral to the construction and landscaping industries. With a commitment to innovation, efficiency, and customer satisfaction, these manufacturers provide the tools necessary for producing high-quality drainage solutions. As urbanization and environmental concerns drive demand for effective rainwater management systems, the importance of reliable downspout forming machine manufacturers will only continue to grow. Investing in advanced machinery from reputable manufacturers not only enhances production capabilities but ultimately contributes to promoting sustainable practices in construction and architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025