Automated Production Systems for Downspout Formation in Manufacturing Facilities

Downspout Forming Machine Factories Revolutionizing Rainwater Management

In the contemporary landscape of construction and architectural design, the efficient management of rainwater is paramount. This need has given rise to various innovative solutions, one of which is the downspout forming machine—a key player in producing effective rainwater drainage systems. Factories that specialize in manufacturing downspout forming machines are now central to the building industry, providing vital equipment that facilitates the creation of high-quality downspouts.

Understanding Downspouts

Downspouts are vertical pipes that direct rainwater collected from roof gutters down to the ground or drainage systems. They play a crucial role in preventing water damage to buildings, minimizing soil erosion, and managing water runoff. Given their importance, the design and material quality of downspouts are critical to their effectiveness. This is where downspout forming machines come into play.

The Role of Downspout Forming Machines

Downspout forming machines are designed to produce downspouts from various materials, typically metals like aluminum, stainless steel, and galvanized steel. These machines can create downspouts in different profiles, sizes, and shapes, allowing manufacturers to meet diverse client needs. The automation provided by these machines not only increases production efficiency but also ensures precision in the dimensions and quality of the output, reducing waste and labor costs.

Types of Downspout Forming Machines

Downspout forming machines come in various types, each tailored for specific manufacturing needs. Some machines are manual, requiring operators to guide the material through the forming process. Others are fully automated, featuring advanced technology that can enhance efficiency and consistency.

1. Roll Forming Machines These are commonly used to create continuous sheets of materials that are then cut into the desired lengths for downspouts. Roll forming machines can produce high volumes of product quickly and are known for their durability and energy efficiency.

2. Hydraulic Press Machines Often used for custom designs, hydraulic presses can shape materials with a high degree of accuracy and strength. They allow for the production of intricate designs that are sometimes required in architectural projects.

3. CNC Machines Computer Numerical Control (CNC) machines are at the forefront of technology in manufacturing. They provide unparalleled precision and can be programmed to create complex shapes and profiles, making them ideal for specialized downspout designs.

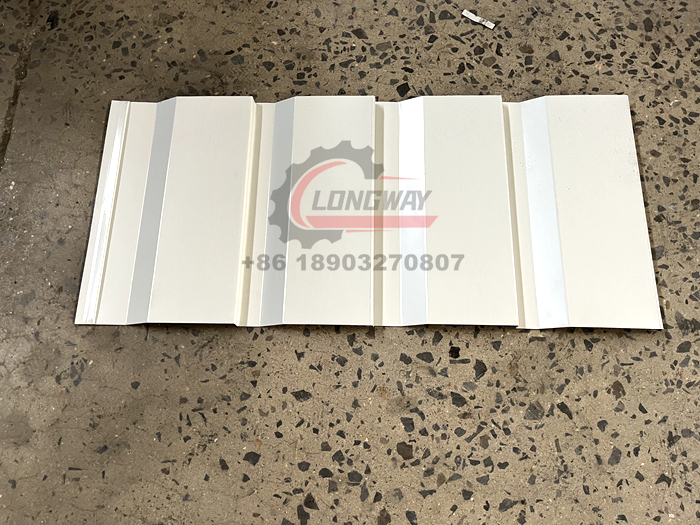

downspout forming machine factories

The Manufacturing Process

The manufacturing process for downspout forming machines typically involves several stages

1. Material Preparation Raw materials, which are usually metal sheets, undergo preparation, including cutting to size and cleaning.

2. Forming The prepared sheets are fed into the machine, where they are shaped into downspouts. Depending on the machine type, this stage may involve cold rolling, bending, or pressing.

3. Finishing Once formed, downspouts often require finishing touches, such as coating or painting, to enhance durability and aesthetic appeal.

4. Quality Control Rigorous quality control measures are implemented to ensure that the finished products meet industry standards and customer specifications.

The Importance of Downspout Forming Machine Factories

Factories specializing in downspout forming machines play a vital role in the construction supply chain. By providing high-quality machinery, they enable manufacturers to produce effective rainwater management systems at scale. Moreover, these factories are often at the forefront of technological advancements, integrating features like automation and improved material handling to optimize production processes.

Conclusion

As the demand for effective water management systems continues to grow, the importance of downspout forming machines cannot be overstated. Factories engaged in their production are not just manufacturers; they are integral to sustainability in construction, helping to reduce water-related risks and ensuring the longevity of structures. By embracing innovation and quality, downspout forming machine factories contribute significantly to modern building practices, paving the way for a robust infrastructure capable of tackling the challenges posed by climate change and urbanization.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025