downspout elbow machine factories

Downspout Elbow Machine Factories Revolutionizing Gutter Manufacturing

In the realm of construction and home improvement, downspouts play a critical role in managing rainwater effectively. These vertical pipes, connected to the gutters, channel water away from the foundation of buildings, preventing flooding and structural damage. One essential component of downspouts is the elbow, which allows for directional changes in piping. The manufacturing of downspout elbow machines has emerged as a crucial industry, catering to the increasing demand for efficient and reliable rainwater management systems.

Importance of Downspout Elbow Machines

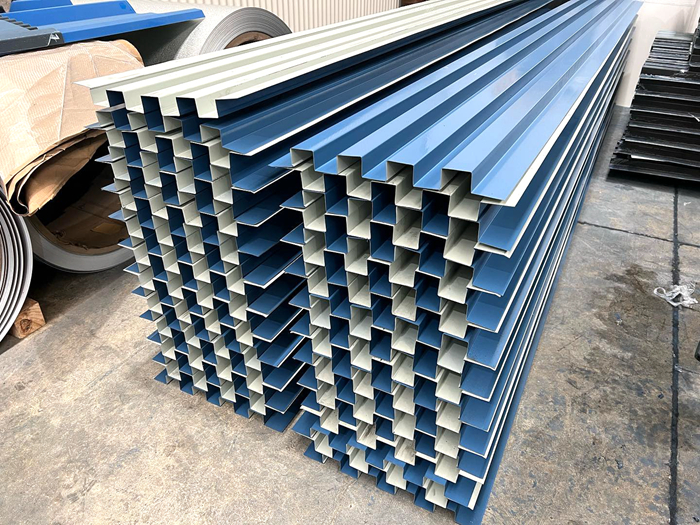

Downspout elbow machines are specialized equipment designed for the production of downspout elbows in various shapes and sizes. These machines are notable for their ability to produce high-quality products with precision, speed, and efficiency. The manufacturing process often involves techniques such as roll forming, bending, and cutting, which can be automated to meet the high production demands of modern construction projects.

The importance of downspout elbow machines in the market cannot be overstated. With the surge in construction activities globally, especially in urban areas, the demand for effective drainage systems has increased significantly. Poor drainage can lead to serious building issues, including moisture intrusion, mold growth, and foundational instability. Therefore, having a reliable source for downspout elbows is vital for builders and contractors.

Features of Downspout Elbow Machines

Factories specializing in downspout elbow machines have integrated advanced technologies to enhance production capabilities. Some key features of these machines include

1. Automated Production Many modern machines are equipped with computer numerical control (CNC) systems that allow for precise cutting and shaping of materials. Automation not only improves accuracy but also increases production speed, meeting the demands of large-scale operations.

2. Versatile Design Downspout elbow machines are designed to work with various materials, including aluminum, steel, and PVC. This versatility allows manufacturers to cater to diverse market needs and preferences, offering customized solutions for different applications.

downspout elbow machine factories

3. Energy Efficiency With a growing emphasis on sustainability, many factories are adopting energy-efficient technologies. This includes using motors and drives that significantly reduce energy consumption during production, thereby lowering operational costs and their carbon footprint.

4. Quality Control Systems Advanced quality control mechanisms are incorporated into the production line to ensure that every elbow produced meets stringent standards. This includes automated inspections and measurements at various stages of production, guaranteeing product reliability and reducing waste.

The Market for Downspout Elbow Machines

As construction trends shift towards sustainable and efficient building practices, the market for downspout elbow machines is expected to grow exponentially. Builders are increasingly prioritizing high-quality drainage systems, making the need for reliable manufacturing capabilities paramount.

Countries with booming construction economies, such as the United States, China, and India, present significant opportunities for downspout elbow machine factories. The rise of DIY culture and home improvement projects further fuels the demand for downspout products, as homeowners seek to enhance or repair their drainage systems.

Moreover, the trend of lightweight and durable materials in construction is driving innovation in the production of downspout elbows. Factories are continually researching and developing new techniques to improve material strength while reducing weight, allowing for easier installation and better performance.

Conclusion

The future of downspout elbow machine factories is bright as they adapt to the ever-evolving construction landscape. By leveraging advanced technology, maintaining high standards of quality, and responding to market demands, these factories play a crucial role in ensuring effective rainwater management. As awareness of the importance of proper drainage systems continues to grow, the significance of downspout elbow machines will only increase, solidifying their place in the construction industry.

In conclusion, investing in high-quality downspout elbow machines not only meets current demands but also prepares factories for the future challenges of a rapidly changing market. Embracing innovation and sustainability will be key to thriving in this essential sector, ultimately benefiting builders, homeowners, and the environment alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025