Manufacturers of Machines for Downspout Elbows and Related Components

The Importance of Downspout Elbow Machines in Manufacturing

In the world of construction and architecture, the effectiveness of drainage systems plays a critical role in maintaining the integrity of buildings and infrastructure. At the heart of these systems are downspouts, which are crucial for directing rainwater from roofs to the ground and preventing water damage. A pivotal component of downspouts is the downspout elbow, which allows for directional changes in the downspout system. The production of these elbows requires specialized machinery, leading to the emergence of downspout elbow machine factories.

Understanding Downspout Elbows

Downspout elbows, typically made from durable materials such as aluminum, vinyl, or galvanized steel, are essential for connecting straight sections of downspouts. Their primary function is to facilitate the effective flow of water away from the building’s foundation. However, not all downspout elbows are created equal. The design and manufacturing process significantly influence their performance, which is where downspout elbow machines come into play.

These machines automate the fabrication of downspout elbows, ensuring that they meet the required specifications for size, shape, and strength. By utilizing advanced technology, these machines can produce elbows that minimize water leakage and structural weaknesses, essential for maintaining a reliable drainage system.

The Manufacturing Process

The operation of downspout elbow machine factories involves several key steps. The first stage in the production process is material selection. Factories typically use high-quality materials that can withstand harsh weather conditions and prevent corrosion. Aluminum and galvanized steel are favored for their lightweight properties and resistance to rust, making them ideal for outdoor use.

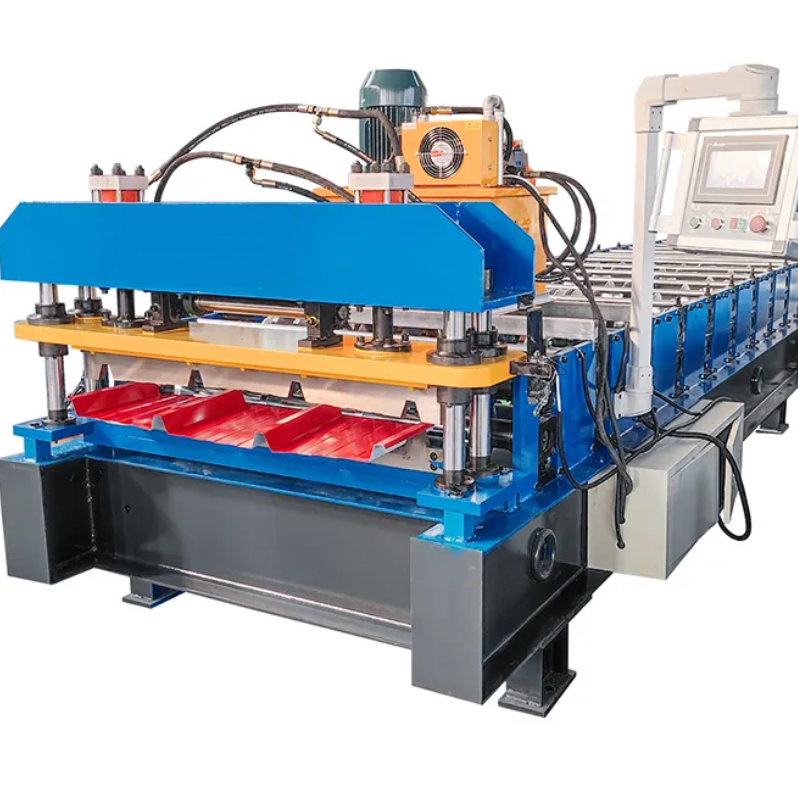

Once the materials are selected, they are fed into the downspout elbow machine, which performs a series of processes that include cutting, bending, and forming. Modern machines come equipped with Computer Numerical Control (CNC) technology, allowing for precise cuts and bends. This precision is crucial, as even slight deviations can lead to poor-fitting connections that compromise the entire drainage system.

downspout elbow machine factories

The bending process, in particular, is critical. Downspout elbows must be shaped at specific angles—usually 90 or 45 degrees—to ensure optimal water flow. Consequently, machines are designed to create these bends without damaging the material, maintaining its structural integrity. After bending, the formed elbows undergo quality control procedures to ensure they meet the industry standards.

Automation and Advancements

In recent years, the downspout elbow machine industry has embraced automation and technological advancements. Factories have begun integrating robotics and AI into their manufacturing processes, allowing for greater efficiency and output. Automated systems can monitor production in real-time, identifying and rectifying any inconsistencies immediately. This not only improves product quality but also reduces waste and operational costs.

Furthermore, advancements in materials technology have allowed for the development of more durable and lightweight products. For instance, the introduction of composite materials presents a new frontier in downspout elbow manufacturing. Factories that adapt to these innovations can provide their clients with a wider range of products, catering to various environmental and structural requirements.

Conclusion

Downspout elbow machine factories play a vital role in the construction industry by ensuring the efficient manufacture of crucial drainage components. As technology continues to evolve, these factories are well-positioned to enhance their production methods, focusing on automation and quality assurance. By producing high-quality downspout elbows, they contribute to the effectiveness and reliability of drainage systems, safeguarding buildings against water damage.

As urban development continues to expand, the demand for efficient drainage solutions will only grow, making the expertise and innovation found in downspout elbow machine factories more valuable than ever. Investing in such technology not only facilitates better construction practices but also promotes sustainability in building design—ultimately leading to safer and more resilient urban environments. Through ongoing advancements and a commitment to quality, these factories are integral in shaping the future of construction and architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025