High-Quality Downspout Making Machine Manufacturer | Efficient and Durable Solutions

The Rise of Downspout Making Machine Companies

In today’s world of construction and home improvement, the demand for efficient and reliable machinery has surged. Among the myriad of equipment needed for various projects, downspout making machines have gained significant attention. These machines play a crucial role in the manufacturing of downspouts, an essential component in gutter systems designed to direct rainwater away from buildings. As climate change intensifies weather patterns, the importance of effective drainage systems becomes ever more critical. Consequently, several companies have emerged as leaders in the production of downspout making machines, catering to a growing market that values efficiency and quality.

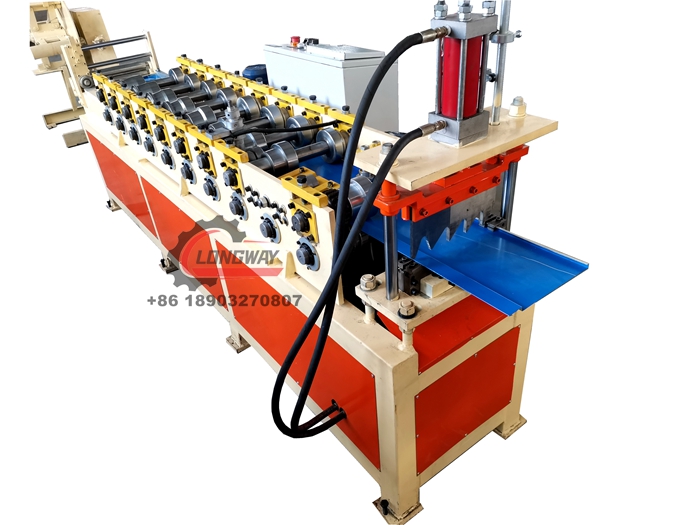

Downspout making machines are engineered to streamline the production of downspouts from materials like aluminum and galvanized steel. These machines can efficiently form, cut, and sometimes even paint these downspouts to meet specific customer requirements. Companies in this niche are leveraging advanced technology to automate processes, reducing both labor costs and the likelihood of human error. This automation not only speeds up production but also allows manufacturers to scale their operations to meet increasing demand.

One prominent feature of modern downspout making machines is their ability to produce a variety of shapes and sizes. Customization is key in the construction industry, where one-size-fits-all solutions often do not suffice. Leading companies have responded by designing machines capable of making downspouts in different configurations, ensuring that contractors and builders can find exactly what they need for their projects.

As competition among downspout making machine manufacturers intensifies, the focus on quality control has also increased. Leading firms implement rigorous testing protocols to ensure their machines consistently produce top-notch products. This attention to detail not only enhances consumer trust but also helps companies maintain their reputations in a burgeoning market.

downspout making machine companies

Sustainability is another significant trend influencing the downspout making industry. Many companies are investing in machines that utilize recyclable materials, reducing waste and environmental impact. By producing downspouts that are durable and recyclable, manufacturers are aligning with global sustainability goals, appealing to environmentally conscious consumers.

Furthermore, the digitalization of manufacturing processes has become a game-changer for downspout making companies. The integration of smart technology in machines allows for better data tracking and predictive maintenance, minimizing downtime and maximizing productivity. Additionally, with the rise of e-commerce, these companies are exploring online platforms to market their machinery, allowing customers to make informed purchasing decisions from the comfort of their homes.

International trade also plays a significant role in the growth of downspout making machine companies. With an expanding market that transcends borders, many manufacturers are now seeking opportunities to export their technologies. This globalization of trade has led to the exchange of ideas and innovations, fostering a culture of continuous improvement within the industry.

In conclusion, the surge in downspout making machine companies reflects broader trends in construction and sustainability. As the demand for efficient and customizable drainage solutions rises, these manufacturers are meeting that demand with innovative, high-quality machinery. The future of this industry looks promising, particularly as companies continue to embrace technology and adapt to changing consumer needs. By prioritizing quality, sustainability, and efficiency, downspout making machine companies are well-positioned to thrive in an increasingly competitive landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025