High-Quality Downpipe Roll Forming Equipment Manufacturing Solutions for Efficient Production

Downpipe Roll Forming Machine Factory An Overview of Innovation and Efficiency

In the realm of modern manufacturing, the demand for high-quality, cost-effective components has never been greater. One of the standout solutions to meet this demand is the downpipe roll forming machine. These machines are specifically designed to produce downpipes—essential components used in drainage systems, typically found in residential and commercial buildings. This article explores the intricacies of downpipe roll forming machines, their manufacturing processes, and the benefits originating from a dedicated factory environment.

Understanding Downpipe Roll Forming Machines

Downpipe roll forming machines are specialized equipment that shape flat steel or aluminum coils into precise profiles. This process involves a series of forming rollers that gradually bend the metal into the desired shape, ensuring uniform thickness and dimensional accuracy. The final product is a downpipe— a vital element that channels rainwater from roofs down to drainage systems, preventing water damage and ensuring proper drainage.

Manufacturing Process

The production of downpipe roll forming machines begins with meticulously selecting high-quality raw materials. Typically, manufacturers utilize galvanized steel or aluminum due to their durability and resistance to corrosion. The manufacturing process involves several stages

1. Design and Engineering Skilled engineers design the downpipe profiles, considering various factors such as flow rates and local building codes. Advanced CAD software is often employed to create detailed models.

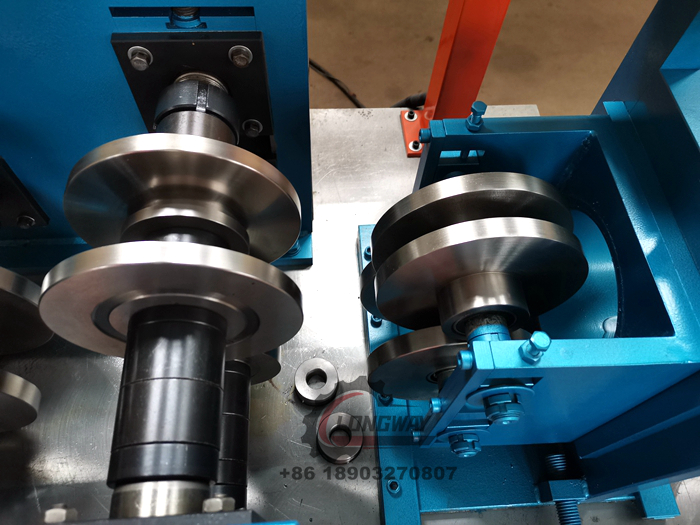

2. Roll Tooling Production Custom rolls are then crafted based on the design specifications. These rolls are essential for shaping the metal into the desired profile during the forming process.

3. Coil Feeding and Forming The machine's automated system feeds the flat coils into the roll forming line. As the coils pass through the series of rollers, they are slowly formed into the downpipe shape, with precision at every stage.

4. Cutting and Finishing After forming, the continuous length of downpipe is cut to the required lengths using high-precision cutting tools. Any additional processes such as coating or painting can also be applied to enhance durability and aesthetics.

downpipe roll forming machine factory

5. Quality Control Throughout the manufacturing process, rigorous quality checks are conducted to ensure that the downpipes meet industry standards. This includes dimensional checks, material tests, and surface inspections.

Benefits of Downpipe Roll Forming Machines

Opting for a downpipe roll forming machine has numerous advantages

- Efficiency These machines significantly reduce production time and labor costs. Automation streamlines the process, allowing manufacturers to produce large volumes of downpipes quickly.

- Customization With advanced engineering capabilities, manufacturers can create downpipes tailored to specific architectural requirements and local regulations.

- Waste Reduction The roll forming process is efficient in material usage, minimizing waste—a crucial aspect in today’s environmentally conscious market.

- Durability The resulting downpipes exhibit superior strength and longevity, which translates to lower maintenance costs and increased satisfaction for clients.

Conclusion

The downpipe roll forming machine factory represents a vital intersection of technology and manufacturing prowess. By continually innovating and improving production methods, these factories can produce high-quality downpipes that meet the demands of a rapidly evolving industry. As construction and infrastructure projects grow globally, the role of downpipe roll forming machines will undoubtedly become even more significant, driving efficiency and sustainability in the market. The future is bright for manufacturers embracing this technology, paving the way for superior building solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025