down pipe roll forming machine exporter

The Down Pipe Roll Forming Machine A Key Export in Metal Fabrication

In the metal fabrication industry, the demand for efficient, high-quality equipment is paramount. One of the standout machines that has drawn a significant amount of attention from both manufacturers and exporters is the down pipe roll forming machine. This specialized piece of equipment is designed to produce downpipes, also known as rainwater pipes or drainpipes, which are essential in any roofing system. In this article, we will delve into the workings of the down pipe roll forming machine, its advantages, and its increasing prominence in export markets.

What is a Down Pipe Roll Forming Machine?

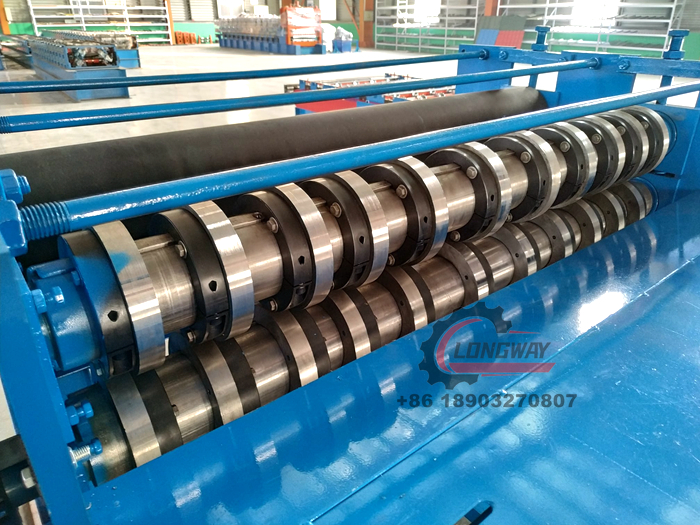

A down pipe roll forming machine is a sophisticated device used to manufacture downpipes from steel coils or sheets. The process begins with the raw material being fed into the machine, which includes several rollers geared towards shaping the material into the desired cross-sectional configuration. As the material passes through these rollers, it gradually takes on the shape of a downpipe, which can be round, square, or rectangular, depending on specifications.

The operation of the roll forming machine is efficient and continuous, allowing for high production rates. This is particularly valuable in commercial applications where large quantities of downpipes are required in a short timeframe. The final products are typically characterized by uniformity, precision, and good surface finish, making them suitable for various construction needs.

Advantages of Down Pipe Roll Forming Machines

1. Cost Efficiency One of the foremost advantages of using down pipe roll forming machines is the reduction in material costs. By utilizing sheet metal efficiently and minimizing waste, manufacturers can produce high-quality downpipes at lower costs.

2. Versatility These machines can often be adjusted to produce downpipes of various sizes and shapes. This versatility allows manufacturers to cater to a diverse range of client needs, from residential to commercial projects.

3. Durability and Strength The downpipes produced using roll forming technology are not only aesthetically pleasing but also robust and resistant to environmental factors. This resilience is crucial in areas susceptible to heavy rain and wind, ensuring that the water drainage system remains intact over time.

down pipe roll forming machine exporter

4. Simplified Manufacturing Process The roll forming process is less labor-intensive compared to other manufacturing techniques. With automation, the machines require minimal manual intervention, reducing labor costs and the potential for human error.

5. High Production Speed The continuous operation of roll forming machines allows for rapid production, enabling manufacturers to meet high demand without compromising quality.

Growing Demand in Export Markets

The global construction industry is witnessing rapid growth, particularly in developing countries. With urbanization on the rise, the demand for efficient drainage systems has skyrocketed, boosting the market for down pipe roll forming machines. As a result, manufacturers from countries with established production capabilities, such as China, have found lucrative opportunities in exporting these machines.

Exporters benefit from the increasing global awareness surrounding the importance of sustainable construction practices. Downpipes, being an integral part of rainwater harvesting systems and efficient drainage solutions, are highly sought after. This trend has encouraged more manufacturers to invest in advanced roll forming technology, thereby enhancing their production capabilities.

Moreover, as environmental regulations and building codes become more stringent in many regions, the demand for high-quality, durable building materials, including downpipes, continues to rise. Exporters who offer reliable down pipe roll forming machines are well positioned to capture this growing market.

Conclusion

The down pipe roll forming machine stands at the intersection of innovation and efficiency in the metal fabrication sector. Its capability to produce high-quality downpipes at speed and cost-effectiveness makes it an invaluable asset to manufacturers. As the global demand for effective drainage solutions continues to expand, the significance of these machines in the export market is only set to increase. Manufacturers and exporters who adapt to these trends will not only enhance their competitiveness but also contribute to the evolution of the construction industry as a whole.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025