Supplier of Double Layer Roll Forming Machines for Efficient Metal Fabrication Solutions

Double Layer Roll Forming Machine Supplier An Essential Guide

In the world of metalworking and construction, the efficiency and precision of fabrication processes are paramount. One of the standout machines that have gained traction in recent years is the double layer roll forming machine. This innovative machinery is designed to produce two types of metal sheets in a single pass, saving both time and resources. In this article, we will explore the importance of selecting an efficient double layer roll forming machine supplier and the benefits of this technology.

Understanding Double Layer Roll Forming Machines

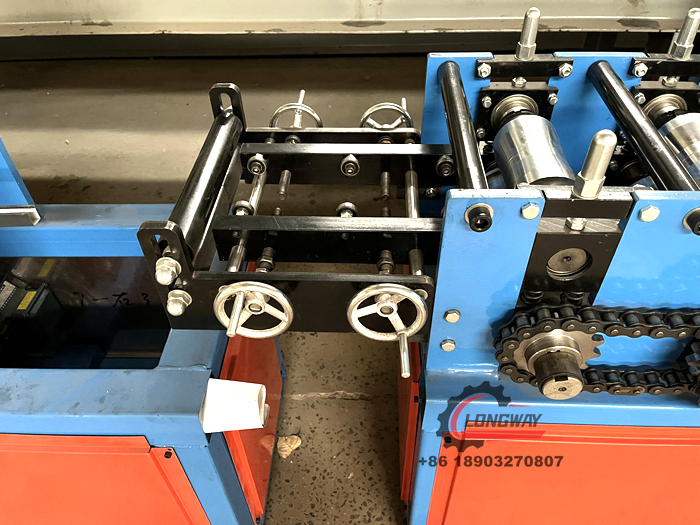

Double layer roll forming machines are specialized equipment that enable manufacturers to create two distinct metal sheets simultaneously. These machines utilize a combination of rollers and forming stations to shape metal strips into profiles like roofing sheets, wall panels, and other structural components. The double layer feature allows for a more compact production line, maximizing output while minimizing space requirements.

Benefits of Double Layer Roll Forming

1. Cost Efficiency By producing two types of sheets at once, manufacturers can reduce the costs associated with labor and material handling. This increased efficiency translates into lower production costs and improved profit margins.

2. Space-Saving Design Traditional roll forming lines often require extensive space for separate machines. Double layer roll forming machines consolidate this process into a single unit, making them ideal for manufacturers operating in limited spaces.

3. Versatility These machines can cater to various applications, producing different profiles depending on the requirements. This versatility ensures that manufacturers can meet diverse customer demands without needing multiple machines.

4. Improved Cycle Times The ability to produce two types of sheets simultaneously significantly reduces cycle times. This speed is advantageous in industries where timeliness is critical.

5. Reduced Material Waste Optimized roll forming processes lead to less scrap material, contributing to sustainable manufacturing practices and lowering overall costs.

Choosing the Right Supplier

double layer roll forming machine supplier

When it comes to investing in a double layer roll forming machine, selecting a reputable supplier is crucial. Here are some key factors to consider

1. Experience and Expertise A supplier with a proven track record in manufacturing roll forming machines is more likely to provide quality products that meet industry standards.

2. Customization Options Each operation is unique, and a good supplier should offer flexibility in customizing machines to meet specific needs. This may include variations in dimensions, materials used, and profile designs.

3. Quality Assurance Ensure that the supplier adheres to strict quality control measures. Machines should pass rigorous testing phases to guarantee durability and performance.

4. After-Sales Support Reliable customer support is essential for maintenance and troubleshooting. A supplier that provides comprehensive after-sales services can help ensure the longevity of the equipment.

5. Technology and Innovation Look for suppliers that invest in the latest technology and innovations. Features like automated controls, energy efficiency, and user-friendly interfaces can greatly enhance the production process.

Market Trends

The market for roll forming machines, particularly double layer models, is experiencing growth due to rising construction activities and increasing investments in infrastructure. The competitive landscape is gradually shifting towards suppliers that offer advanced technological solutions, contributing to more efficient production lines.

Moreover, as industries move towards sustainability, suppliers that provide energy-efficient machines and use eco-friendly materials in their manufacturing processes are gaining an edge. This shift highlights the importance of selecting a supplier who is not only focused on machinery but also on sustainable practices.

Conclusion

Investing in a double layer roll forming machine can significantly enhance production efficiency and reliability in various sectors. Selecting the right supplier is crucial for capitalizing on the numerous benefits this machine has to offer. By considering factors such as experience, customization options, quality assurance, and technological advancements, manufacturers can ensure they choose a partner that supports their growth and manufacturing goals. With the ongoing demand for efficient and versatile manufacturing solutions, the role of a trusted double layer roll forming machine supplier cannot be overstated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025