Jan . 19, 2025 04:42

Back to list

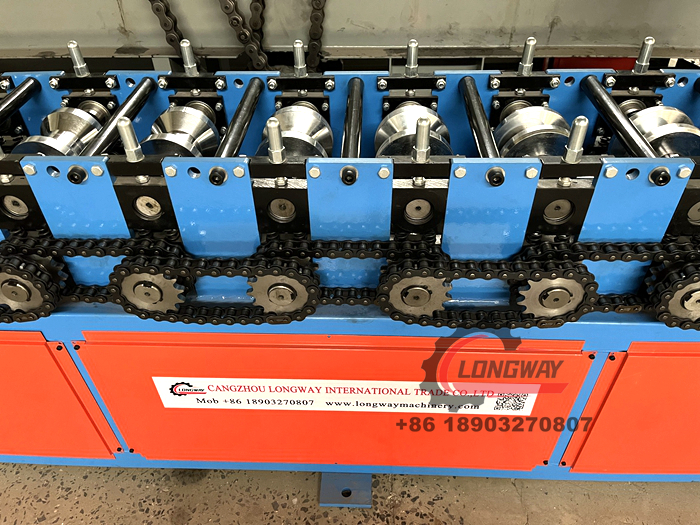

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

In the niche yet rapidly burgeoning industry of manufacturing, the double layer roll forming machine stands as a testament to modern engineering ingenuity. These machines are uniquely designed to simultaneously produce two distinct profiles on a single machine, thus optimizing both space and resources. The ability to efficiently switch between profiles without extensive downtime exemplifies the kind of innovation that defines the advancement of roll forming technology.

Trustworthiness in the field of double layer roll forming machines is accentuated by the consistency in the performance of these machines. Customers demand machines that deliver the desired output with minimal maintenance and downtime. To this end, leading manufacturers provide robust after-sales support and comprehensive warranties that address any potential operational issues. Testimonials from industries utilizing these machines affirm their satisfaction with the decreased costs in labor and increased production throughput, reinforcing the machine's credibility in delivering as promised. For those considering the investment, thorough research is paramount. Evaluate the technical specifications, the customization possibilities, and after-sales service when selecting a machine. Partnering with a manufacturer that offers comprehensive technical support can mitigate future challenges and ensure the machine’s seamless integration into existing production lines. The future of manufacturing is leaning heavily on such innovations to meet the increasing demands for efficiency and versatility. Double layer roll forming machines represent a sharpened edge in metal forming technology, sculpting the future with their ability to provide quality and precision. Users who leverage these machines will inevitably find themselves at a strategic advantage in the global marketplace, paving the way for industry dominance through superior operational capabilities.

Trustworthiness in the field of double layer roll forming machines is accentuated by the consistency in the performance of these machines. Customers demand machines that deliver the desired output with minimal maintenance and downtime. To this end, leading manufacturers provide robust after-sales support and comprehensive warranties that address any potential operational issues. Testimonials from industries utilizing these machines affirm their satisfaction with the decreased costs in labor and increased production throughput, reinforcing the machine's credibility in delivering as promised. For those considering the investment, thorough research is paramount. Evaluate the technical specifications, the customization possibilities, and after-sales service when selecting a machine. Partnering with a manufacturer that offers comprehensive technical support can mitigate future challenges and ensure the machine’s seamless integration into existing production lines. The future of manufacturing is leaning heavily on such innovations to meet the increasing demands for efficiency and versatility. Double layer roll forming machines represent a sharpened edge in metal forming technology, sculpting the future with their ability to provide quality and precision. Users who leverage these machines will inevitably find themselves at a strategic advantage in the global marketplace, paving the way for industry dominance through superior operational capabilities.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products