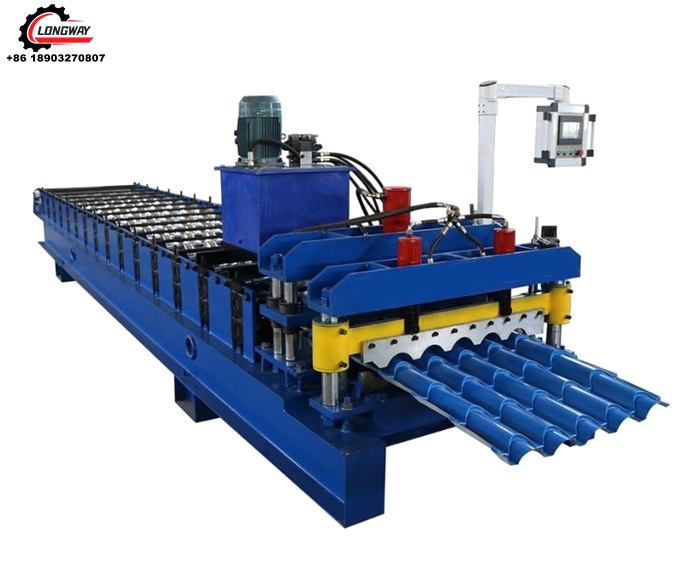

double layer cold roll forming machine

Double Layer Cold Roll Forming Machine Revolutionizing Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency, versatility, and precision are paramount. Among the myriad of technologies making waves in the industry, the double layer cold roll forming machine stands out as a game-changer, particularly in the production of building materials and the construction sector. This innovative machinery combines two different profiles in a single run, allowing manufacturers to produce multiple products without the need for multiple machines, thereby optimizing operational throughput and resource utilization.

Understanding Cold Roll Forming

Cold roll forming is a process where metal sheets or strips are shaped into desired profiles at room temperature. This method is particularly advantageous because it allows the metal to retain its original properties while achieving significantly improved strength through work hardening. In contrast to hot forming, which requires heating the metal before molding, cold roll forming maintains a more efficient and flexible production process, resulting in lower energy consumption and reduced environmental impact.

The Concept of Double Layer Forming

The double layer cold roll forming machine operates on this principle but adds an innovative twist. By enabling the simultaneous formation of two different profiles—such as C and Z purlins or various roofing sheets—it significantly increases production efficiency and reduces manufacturing costs. Traditional methods would require separate machines and runs to achieve these distinct profiles. However, with a double layer machine, manufacturers can streamline their operations, thus saving time, labor, and material costs.

Key Features and Benefits

1. Versatility One of the most notable advantages of the double layer cold roll forming machine is its versatility. It can produce a wide range of products suited for various applications, including roofing panels, wall panels, and purlins. This adaptability allows manufacturers to respond to diverse market demands without the need for significant investment in new machinery.

2. Space Efficiency In manufacturing plants where floor space is at a premium, double layer machines offer a compact solution. By combining two production lines into one, companies can maximize their output while minimizing their physical footprint.

double layer cold roll forming machine

3. Cost-Effectiveness Combining the processes into one machine reduces capital investment and maintenance costs. Additionally, the reduction in setup time between runs translates into increased productivity and profitability for manufacturers.

4. Quality and Precision Modern double layer cold roll forming machines come equipped with advanced technologies, including computer numerical control (CNC) systems. These sophisticated controls ensure high precision, consistent quality, and reduced waste, further enhancing the cost efficiency of the production process.

5. Easy Operation and Maintenance With user-friendly interfaces and smart design, these machines simplify both operation and maintenance. Operators can easily switch between profiles with minimal downtime, ensuring a smooth workflow.

Applications in Construction

The construction industry has been one of the primary beneficiaries of this technology. The ability to produce high-quality materials quickly and efficiently is crucial in a sector where deadlines and budgets are tight. Double layer cold roll forming machines facilitate the rapid production of lightweight structures, making them ideal for residential, commercial, and industrial applications.

Moreover, given the growing emphasis on sustainable building practices, the efficiency of cold roll forming technologies aligns perfectly with the industry's move towards eco-friendliness. The reduced energy consumption and minimized material waste contribute to a lower environmental footprint, meeting the increasing demands for sustainability.

Conclusion

In an era where efficiency and adaptability define success in manufacturing, the double layer cold roll forming machine emerges as a vital tool for businesses seeking to improve their productivity and competitiveness. With its ability to produce two different profiles simultaneously, it not only enhances operational efficiency but also addresses the diverse needs of the construction industry. As technology continues to evolve, we can expect that machines like these will play an increasingly central role in modern manufacturing, paving the way for innovative solutions and sustainable practices in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025