double layer cold roll forming machine

Understanding Double Layer Cold Roll Forming Machines

In modern manufacturing, the efficiency and versatility of production processes play a crucial role in meeting the demands of various industries. One notable innovation in this regard is the double layer cold roll forming machine. This piece of equipment has revolutionized the way that sheet metal products are fabricated, offering numerous advantages in terms of efficiency, space-saving, and product diversity.

What is a Double Layer Cold Roll Forming Machine?

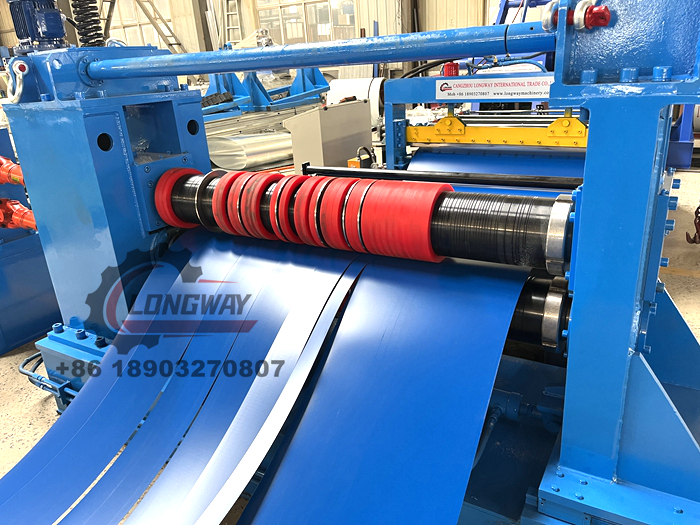

A double layer cold roll forming machine is designed to produce two different profiles or layers of metal sheets simultaneously. Unlike traditional roll forming machines that create a single profile, this advanced technology allows manufacturers to maximize output by processing two designs in one pass. The machine typically consists of a set of rollers that reshape the raw metal strips into predefined shapes as they pass through the forming station.

Key Advantages

1. Space Efficiency One of the most significant advantages of a double layer cold roll forming machine is its ability to save space. Since it produces two profiles concurrently, manufacturers can reduce the overall footprint of their production line. This is particularly beneficial for small to mid-sized factories where space is a premium.

2. Increased Productivity By operating two layers simultaneously, these machines can nearly double the production output compared to single-layer systems. This increased efficiency helps businesses meet growing market demands while minimizing labor costs and machine operation time.

double layer cold roll forming machine

3. Cost-Effectiveness The dual functionality of these machines translates into reduced operational costs. Fewer machines are needed to produce multiple profiles, leading to lower maintenance and energy expenses. Moreover, with higher output rates, companies can take advantage of economies of scale, ultimately enhancing their profitability.

4. Versatility Double layer cold roll forming machines can be customized to produce a wide variety of profiles and materials. Whether it’s roofing sheets, wall panels, or other structural components, these machines can handle different gauge metals, including galvanized steel, aluminum, and stainless steel. This versatility makes them ideal for a range of industries, from construction to automotive manufacturing.

5. Quality and Precision Another significant benefit is the high level of precision achieved during the forming process. Modern double layer machines are equipped with advanced technology that ensures uniform thickness and minimal deviation in dimensions. This characteristic is particularly important for industries that require exact specifications for safety and structural integrity.

Applications

Double layer cold roll forming machines are prevalent in various sectors. In the construction industry, they are widely used to produce roofing, cladding, and wall profiling. In the automotive industry, these machines can manufacture parts that require specific shapes and tolerances. Additionally, they are utilized in the manufacturing of furniture and appliances, producing components that require both aesthetic appeal and functional reliability.

Conclusion

The double layer cold roll forming machine is a testament to the advancements in manufacturing technology. Its ability to produce two distinct profiles in one operation not only enhances productivity and cost-effectiveness but also provides flexibility and quality assurance. As industries continue to evolve and demand more efficient production methods, the role of double layer machines is likely to grow, making them an integral part of modern manufacturing processes. Embracing such innovations is key for businesses aiming to maintain a competitive edge and respond swiftly to market trends. As we move forward, we can expect continuous improvements and adaptations in this technology, further redefining the landscape of metal forming and manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025