double deck roll forming machine manufacturers

Double Deck Roll Forming Machine Manufacturers Revolutionizing Metal Fabrication

In the rapidly evolving industry of metal fabrication, the demand for high-quality and efficient production equipment has never been more critical. Among the various innovations in this sector, the double deck roll forming machine stands out as a remarkable advancement. This specialized equipment is designed to create various metal profiles and components with precision and efficiency. As a result, manufacturers in this field have become crucial players in supporting industries ranging from construction to automotive and beyond.

Understanding Double Deck Roll Forming Machines

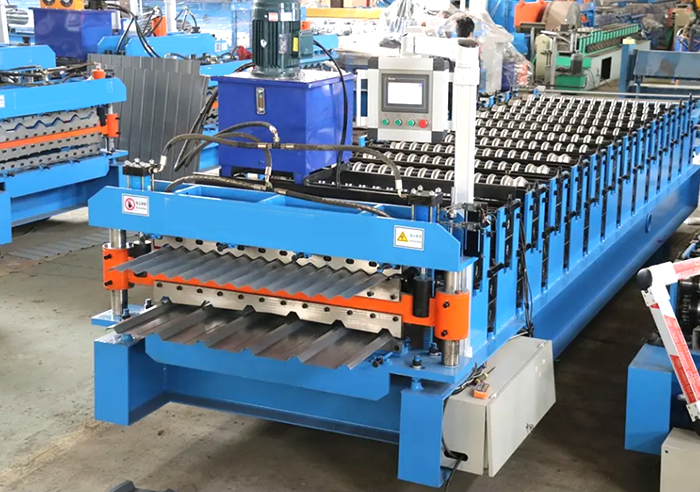

Double deck roll forming machines are sophisticated devices that use a continuous bending method to process metal sheets into desired shapes. Unlike traditional roll forming machines, which typically create a single profile, double deck machines can produce two different profiles simultaneously. This capability significantly increases productivity and is particularly beneficial in high-demand environments where time and resource efficiency are paramount.

The design of these machines allows for distinct metal profiles to be formed on separate levels or decks. Each deck operates independently, enabling manufacturers to create diverse products without needing multiple machines. Common applications include roof panels, wall panels, and other construction materials, making these machines integral to modern manufacturing processes.

The Role of Manufacturers

The success of double deck roll forming machines hinges on the expertise and innovation of manufacturers in this field. Leading companies invest heavily in research and development to enhance machine capabilities, improve automation, and develop user-friendly interfaces. They also focus on incorporating energy-efficient technologies and advanced control systems to minimize waste and maximize production rates.

Manufacturers often offer customized solutions to meet the specific needs of their clients. By collaborating closely with customers, they can design machines that cater to unique specifications, including profile shapes, material thickness, and production speeds. This level of customization is crucial in maintaining a competitive edge in the market and ensuring customer satisfaction.

double deck roll forming machine manufacturers

Quality and Reliability

One of the foremost concerns for buyers is the quality and reliability of the machinery they invest in. Leading double deck roll forming machine manufacturers adhere to rigorous quality standards and certifications. They often use high-grade materials and advanced engineering techniques to ensure longevity and performance. Quality assurance processes, including rigorous testing and inspection, are essential to delivering machines that can withstand the demands of continuous operation.

Additionally, manufacturers understand that after-sales support is vital. Providing comprehensive warranties, maintenance services, and readily available spare parts significantly enhances the customer experience. This ongoing relationship fosters trust and encourages repeat business, essential for manufacturers aiming for long-term success.

Future Trends

As the industry continues to evolve, several trends are likely to shape the future of double deck roll forming machines. Automation and smart technologies are at the forefront, allowing for greater efficiency and precision in production. Manufacturers are increasingly integrating IoT (Internet of Things) capabilities into their machines, enabling real-time monitoring and data analysis. This trend not only enhances operational efficiency but also allows manufacturers to anticipate maintenance needs and reduce downtime.

Sustainability is another critical area of focus. As global awareness of environmental issues rises, manufacturers are exploring eco-friendly practices, such as optimizing energy consumption and minimizing material waste.

In conclusion, double deck roll forming machine manufacturers play a pivotal role in the modernization of metal fabrication. By embracing innovation and commitment to quality, these manufacturers are poised to lead the industry into a future marked by efficiency, sustainability, and exceptional production capabilities. For businesses seeking to enhance their manufacturing processes, investing in high-quality double deck roll forming machines is a forward-thinking choice that promises substantial returns.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025