double deck roll forming machine companies

The Significance of Double Deck Roll Forming Machine Companies in Modern Manufacturing

In the intricate world of modern manufacturing, the necessity for efficient and versatile machinery is paramount. One such innovation that has revolutionized the way metal components are processed is the double deck roll forming machine. This sophisticated equipment is widely used to produce a wide range of profiles and components across various industries, including construction, automotive, and appliances. Companies dedicated to manufacturing these machines play a crucial role in enhancing productivity and ensuring high-quality outputs.

Understanding Double Deck Roll Forming Machines

Double deck roll forming machines are engineered to operate two separate lines of roll forming simultaneously. This innovative design allows manufacturers to produce two different profiles in a single pass, significantly optimizing production workflows. The capability to work on multiple layers means that companies can meet diverse customer demands while maximizing their machine utilization.

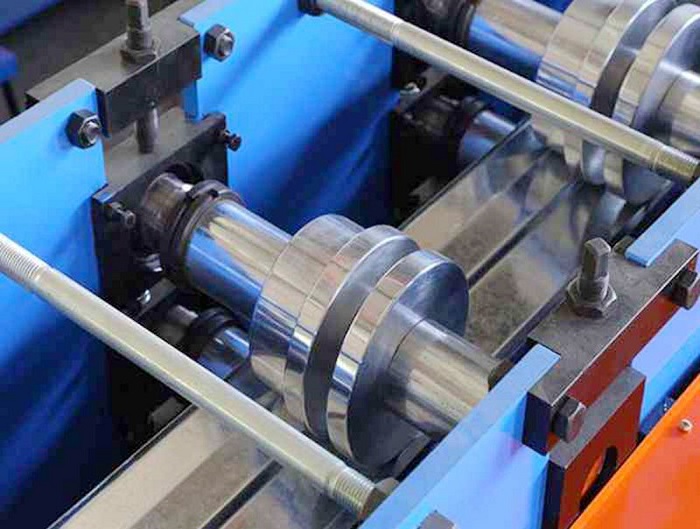

The typical process involves feeding a flat metal sheet into the machine, which then passes through a series of rollers. These rollers shape the material into the desired profile, providing precision that is unmatchable by many other forming techniques. The double deck configuration not only increases efficiency but also reduces manual handling and the time typically required for switching between molds, thereby reducing downtime.

The Competitive Landscape

The landscape of companies manufacturing double deck roll forming machines is marked by innovation and competitiveness. Industry leaders continually invest in research and development to enhance the efficiency, speed, and precision of their machines. Not only must these companies provide robust machinery, but they also need to adapt to ever-changing market demands and technological advancements.

Companies in this sector often offer customization options, allowing clients to tailor machines to their specific production needs. From varying the widths of the profiles to integrating advanced controls and safety features, manufacturers strive to meet the diverse requirements of their customer base. Moreover, in an era focused on sustainability, many companies are also working toward more eco-friendly technologies that minimize waste and energy consumption.

double deck roll forming machine companies

Global Market Trends

The global market for double deck roll forming machines is experiencing considerable growth, driven by the increasing demand for lightweight yet durable materials in construction and automotive sectors. As businesses seek to enhance their production capabilities, the adoption of advanced roll forming technologies is accelerating.

Emerging markets, particularly in Asia and South America, are also driving demand, as infrastructure development and automotive manufacturing flourish in these regions. This expansion opens doors for international companies to establish partnerships and penetrate these burgeoning markets.

Challenges and Considerations

Despite the promising outlook, companies that manufacture double deck roll forming machines face several challenges. The need for ongoing innovation means that significant investment is required to remain competitive. Furthermore, the ever-evolving regulatory landscape concerning manufacturing practices necessitates continuous adjustments to comply with safety and quality standards.

Supply chain issues can also affect production schedules and the availability of raw materials. Companies must be strategic in their sourcing and logistics to ensure that they can deliver high-quality machinery without unnecessary delays.

Conclusion

In conclusion, double deck roll forming machine companies are pivotal players in the arena of modern manufacturing. Their ability to offer advanced, efficient, and customizable machinery not only meets the growing needs of various industries but also drives forward the market towards higher efficiency and sustainability. As businesses and industries continue to evolve, the significance of such specialized machinery and the companies that produce them will undoubtedly grow, marking an essential element of the manufacturing ecosystem. By harnessing innovation and responding to market dynamics, these companies will continue to shape the future of production processes globally.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025