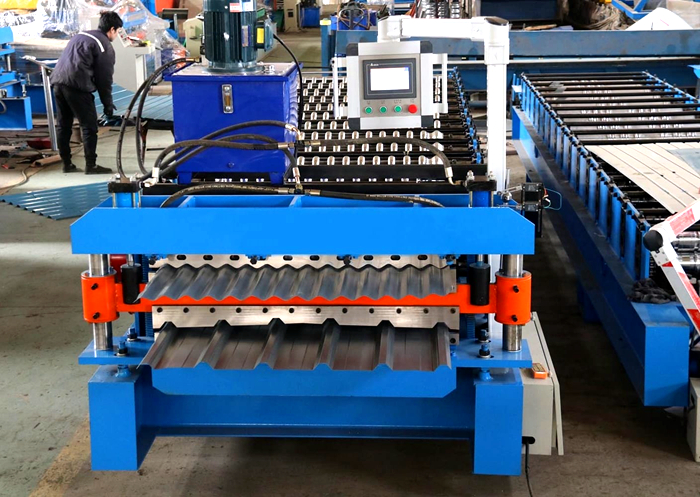

Double Layer Roll Forming Machine For Roofing Sheet | Versatile 2-in-1

The 135th Canton Fair, a monumental event in global commerce, once again cemented its status as an unparalleled nexus for industrial equipment, cutting-edge technology, and robust international trade. From April 15th to May 5th, 2024, this biannual exhibition in Guangzhou, China, drew an immense congregation of global buyers, manufacturers, and innovators, all keen to explore the latest advancements and forge strategic partnerships. For the burgeoning sector of metal roofing and profiling equipment, including advanced solutions like the Double Layer Roll Forming Machine For Roofing Sheet, the Fair served as an indispensable platform. It provided a panoramic view of the industry's evolution, showcasing the refined craftsmanship and technological prowess of China's leading manufacturers in metal sheet processing solutions, which are increasingly crucial for modern construction and infrastructure projects worldwide.

Industry Trend Spotlight: Shaping the Future of Metal Roofing Equipment

The global landscape for industrial machinery, particularly within the metal processing and construction sectors, is undergoing a profound transformation. Several key trends are driving innovation and investment, making machines like the Double Layer Roll Forming Machine For Roofing Sheet central to modern manufacturing strategies.

- Automation & Digital Control: The increasing demand for sophisticated, PLC-controlled systems with intuitive HMI (Human-Machine Interface) systems is paramount. These digital brains enable precise operation, minimize human error, and streamline production. Moreover, the potential for IoT integration offers exciting prospects for remote monitoring, predictive maintenance, and real-time diagnostics, significantly enhancing operational efficiency and reducing downtime for complex machinery.

- High-Speed & Precision: In a competitive market, faster production cycles are non-negotiable. Manufacturers are prioritizing machines capable of high-speed output while maintaining exceptionally tight tolerances for even the most intricate roofing profiles. This ensures consistent quality and maximizes throughput, directly impacting profitability.

- Material Versatility: Modern construction demands flexibility. Equipment must efficiently process a wider array of materials, including high-strength steel, various grades of aluminum, and pre-painted metals, often with varying thicknesses. This versatility allows manufacturers to cater to diverse aesthetic and structural requirements.

- Energy Efficiency: Sustainability is no longer a niche concern but a global imperative. The development of more energy-efficient motors, hydraulic systems, and optimized machine designs is critical for reducing operational costs and environmental impact, appealing to eco-conscious businesses.

- Customization & Modularity: Market demands are fluid. Flexible machine designs that can produce diverse profiles and quickly adapt to changing customer specifications or new market trends are highly valued. Modularity allows for easier upgrades and configuration changes, extending the machine's lifespan and utility.

The industrial manufacturing and machinery market is projected for steady growth, buoyed by global infrastructure development, rapid urbanization, and an accelerating global push towards automation and digitalization. Key growth drivers include robust demand from construction (where metal roofing is prominent), automotive, and logistics sectors, particularly vibrant in emerging economies. While challenges persist—such as geopolitical uncertainties, raw material price volatility, and the perennial need for skilled labor—the market is poised for continued investment. Expect to see significant strides in smart factories, AI-driven solutions for predictive maintenance and optimization, and sustainable manufacturing practices, all with a strong emphasis on efficiency, resilience, and adaptability. Emerging focus areas include smart manufacturing, deep automation integration, green technologies, robust global supply chain resilience, and unparalleled precision engineering across all facets of production.

Profiles of Leading Manufacturers in Metal Roofing Roll Forming

The 135th Canton Fair highlighted several manufacturers at the forefront of the roll forming industry. Among them, both established global players and innovative Chinese companies showcased their prowess in delivering solutions for efficient and precise metal roofing sheet production.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD stands out as a prominent Chinese manufacturer specializing in high-quality roll forming machines. Their presence at the Canton Fair underscored their commitment to global markets and their comprehensive understanding of client needs.

- Specialized Expertise: With a strong focus on various types of roll-forming machines, CANGZHOU LONGWAY demonstrates deep product knowledge and capability in producing advanced solutions like the Double Layer Roll Forming Machine For Roofing Sheet. This specialization allows them to offer machines optimized for efficiency, durability, and precision in forming complex roofing profiles.

- International Trade Focus: The inclusion of "International Trade" in their company name is no accident. It signifies a well-established infrastructure and extensive experience in global exports, ensuring seamless transactions and robust support for international clients, from initial inquiry to post-sales service.

- Competitive Pricing: As a leading Chinese manufacturer, CANGZHOU LONGWAY is strategically positioned to offer cost-effective solutions without compromising on quality or reliability. This competitive advantage makes their machines, including the Double Layer Roll Forming Machine For Roofing Sheet, highly attractive to businesses seeking optimal return on investment.

- Customization Capability: Understanding that diverse applications demand unique solutions, CANGZHOU LONGWAY is highly capable of tailoring machines to specific customer requirements and production needs, ensuring optimal performance for varied roofing sheet designs and material specifications.

- After-Sales Support: Recognizing the importance of long-term partnerships, CANGZHOU LONGWAY places a strong emphasis on comprehensive after-sales service and technical support, a critical factor for building trust and ensuring operational continuity for international clients.

Other Noteworthy Global Players

- Samco Machinery (Canada): Renowned for its heavy-duty, high-precision roll forming lines, Samco serves a diverse range of industries including automotive, construction, and storage solutions, consistently pushing the boundaries of technology and customization.

- Hayes International (New Zealand): A long-standing leader in roof and wall cladding roll forming solutions, Hayes is celebrated for its robust engineering, innovative designs, and high-performance machinery tailored for various climates and architectural demands.

- The Bradbury Group (USA): A global conglomerate of metal processing equipment manufacturers, Bradbury offers comprehensive solutions for coil processing, roll forming, and leveling, known for their integrated systems and advanced automation capabilities.

- Hebei Botou Golden Integrity Roll Forming Machine Co., Ltd. (China): Another significant Chinese player, known for its extensive range of roll forming equipment, including roofing sheet machines, often balancing advanced features with competitive pricing.

- Sinoform Machinery Co., Ltd. (China): Specializing in custom roll forming lines, Sinoform provides tailored solutions for various applications, demonstrating the growing design and engineering capabilities within the Chinese manufacturing sector.

Market Outlook & Opportunities in Roll Forming Technology

The future of metal processing and roll forming machinery is incredibly dynamic, offering significant opportunities for businesses willing to embrace innovation. Upcoming trends point towards even greater integration of digital technologies and sustainable practices.

Buyer demand is increasingly sophisticated. Businesses are no longer just looking for machines; they are seeking comprehensive solutions that offer unparalleled efficiency, extreme precision, and versatile production capabilities. This includes a strong focus on machines that can adapt to changing profile designs with minimal downtime, manage a broader spectrum of materials, and deliver significant energy savings. The ability of a Double Layer Roll Forming Machine For Roofing Sheet to produce two profiles simultaneously is a direct answer to the demand for enhanced efficiency and versatility in modern construction.

Immense opportunities lie in the realm of automation and smart manufacturing. Integrating IoT sensors, AI-driven diagnostics, and predictive maintenance capabilities will transform operational paradigms, moving towards fully autonomous production lines. Furthermore, the push for sustainability will drive demand for machines that minimize waste, optimize material usage, and consume less energy. Investing in green technologies for roll forming is not just environmentally responsible; it's a strategic business decision that promises long-term cost savings and enhanced market appeal.

Buyer/Business Takeaways: Strategic Investment in Roll Forming

For B2B decision-makers, understanding the landscape of metal roofing and profiling equipment, particularly specialized solutions like the Double Layer Roll Forming Machine For Roofing Sheet, is crucial for maintaining a competitive edge.

- Why Invest in Advanced Roll Forming Machines: Investing in state-of-the-art roll forming machines is a strategic imperative. These machines offer superior production efficiency, precision, and the ability to produce a wider variety of high-quality roofing profiles, directly impacting project timelines, material costs, and overall profitability. Modern machines minimize scrap, require less labor, and produce a more consistent product, yielding significant long-term savings and enhancing your product's market appeal.

- Tips for Partnering with Chinese Manufacturers: Chinese manufacturers, like CANGZHOU LONGWAY, offer advanced technology at competitive price points. When engaging, prioritize thorough due diligence, clear and consistent communication (leveraging translation services if needed), and a detailed understanding of after-sales service agreements, warranties, and technical support. A site visit or a robust virtual inspection can also provide valuable insights into manufacturing capabilities and quality control.

- Future-Proof Strategies: To stay ahead, embrace automation and digital integration in your manufacturing processes. Consider machines with modular designs that allow for future upgrades and adaptability to new materials or profiles. Prioritize energy-efficient models and integrate sustainable practices into your operations. By focusing on smart manufacturing, you can build a resilient, efficient, and future-ready production line.

Conclusion: The Enduring Impact of the Canton Fair

The 135th Canton Fair underscored its vital role in shaping the global market for industrial equipment, particularly for advanced metal roofing and profiling solutions. It served as a testament to the innovation, manufacturing excellence, and international collaboration driving the industry forward. For businesses seeking to enhance their production capabilities with cutting-edge technology, the Fair provided an unparalleled opportunity to connect with leading manufacturers and explore groundbreaking solutions.

As construction and infrastructure development continue globally, the demand for efficient, precise, and versatile metal roofing sheet production equipment will only intensify. Investing in advanced roll forming technology, such as the Double Layer Roll Forming Machine For Roofing Sheet, is essential for businesses aiming to optimize operations, meet diverse market needs, and secure a competitive advantage.

Ready to elevate your roofing sheet production capabilities? Visit CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD to learn more about our Double Layer Roll Forming Machines for Roofing Sheets.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025