Roll Forming Machine for Door Shutter Production and Customization Solutions

Understanding Door Shutter Roll Forming Machines A Comprehensive Overview

In the world of manufacturing, efficiency and precision are critical components that drive productivity and quality. Among various machines used in metalworking, the door shutter roll forming machine stands out for its capability to transform raw materials into high-quality finished products. This article provides an in-depth look at door shutter roll forming machines, their applications, and their significance in modern manufacturing.

What is a Door Shutter Roll Forming Machine?

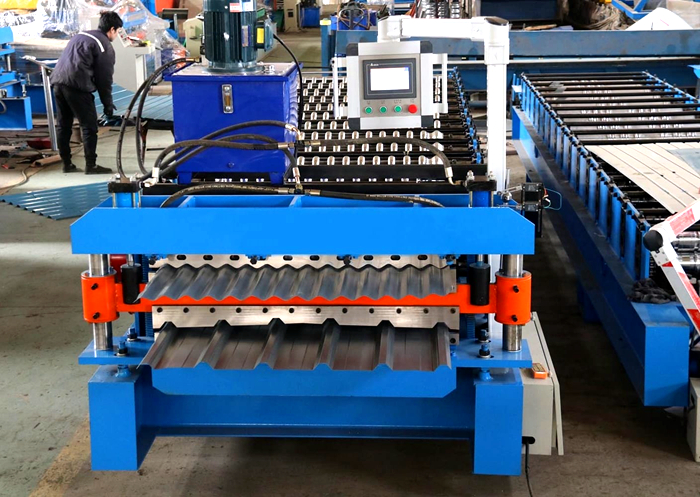

A door shutter roll forming machine is a specialized piece of equipment designed to produce metal door shutters through a process called roll forming. This process involves feeding a continuous sheet of metal - typically galvanized steel or aluminum - into a series of rollers that gradually shape the material into a desired profile. The result is a durable, lightweight, and aesthetically pleasing door shutter that can be used in various applications, including storefronts, garages, and industrial facilities.

Key Features and Components

1. Roll Forming Stations At the heart of the machine are multiple rollers configured in a specific sequence. Each station bends the metal sheet slightly more, gradually achieving the final profile. The number of stations can vary based on the complexity of the shutter design.

2. Material Handling System To ensure smooth operation, these machines are equipped with a material handling system that feeds the metal sheets into the rollers. This system can include a decoiler, which unwinds the metal coil, and a feeding unit that adjusts the speed and alignment of the material.

3. Cutting Mechanism Once the desired length of the shutter is formed, a cutting system is activated to shear the finished product. This can be done through a hydraulic or mechanical cutting module, ensuring clean and accurate cuts.

4. Control System Modern roll forming machines come with advanced control systems that allow for precise adjustments and monitoring of the entire process. Operators can program settings such as speed, pressure, and dimensions directly into the machine.

Applications of Door Shutter Roll Forming Machines

door shutter roll forming machine

Door shutter roll forming machines are widely used in various sectors, including

- Retail and Commercial Spaces These machines produce shutters that provide security for businesses during non-operating hours, offering a deterrent against theft and vandalism. - Residential Use Homeowners often use roll-formed shutters for garage doors, providing both security and insulation. - Industrial Facilities Factories and warehouses utilize heavy-duty roll-formed shutters that withstand harsh environmental conditions and heavy usage.

- Emergency Services Roll-formed metal shutters can also be found in facilities like fire stations, providing quick access while ensuring safety and security.

Benefits of Using Door Shutter Roll Forming Machines

1. Durability The roll forming process produces stronger products than traditional metal fabrication methods, resulting in door shutters that can withstand impact and wear.

2. Cost-Effectiveness Mass production capabilities lower the overall cost per unit. As the machines operate continuously, they can produce large quantities of shutter materials in a shorter timeframe.

3. Customization With various profiles and designs available, manufacturers can easily customize the shutters to meet specific customer needs, ensuring unique solutions for different applications.

4. Reduced Waste The precision of the roll forming process minimizes material waste, making it an environmentally friendlier choice compared to traditional fabrication methods.

Conclusion

Door shutter roll forming machines are integral to modern metal manufacturing, providing reliable and efficient solutions for producing high-quality door shutters. Their versatility, combined with advancements in technology, makes them indispensable for businesses that require durable and aesthetically appealing security solutions. As the demand for secure and attractive building features continues to grow, the importance of these machines in the manufacturing industry will only increase. Investing in a door shutter roll forming machine can lead to substantial benefits for manufacturers, contractors, and consumers alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025