Door Frame Production Equipment for Efficient Manufacturing Solutions

The Door Frame Making Machine Revolutionizing the Manufacturing Process

In recent years, the construction and manufacturing industries have seen significant advancements due to technological innovations. One such innovation that has made a considerable impact is the door frame making machine. This specialized machine is designed to streamline the production of door frames, enhancing efficiency and precision while reducing labor costs and waste.

Understanding Door Frame Making Machines

A door frame making machine is typically an automated system that uses a combination of cutting, shaping, and assembling techniques to produce door frames from raw materials such as wood or metal. These machines can vary in complexity, from simple manual setups to advanced fully automated systems featuring computer numerical control (CNC) technology.

The primary function of a door frame making machine is to create frames that can be used for various types of doors, including residential, commercial, and industrial applications. With the increasing demand for customized solutions, modern machines are equipped to handle various sizes and designs, catering to specific customer requirements.

Key Features and Components

Door frame making machines come equipped with several critical features that enhance their functionality

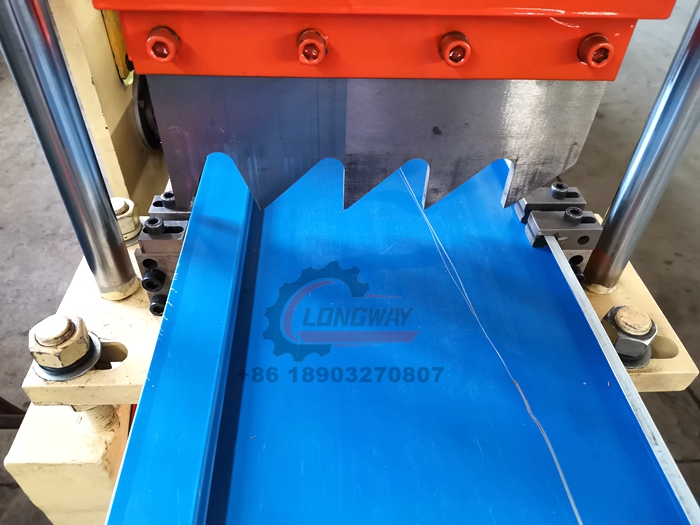

1. Cutting Mechanism Precision cutting tools are used to create accurate dimensions and shapes for the door frames. High-speed saws or laser cutting technology ensure clean cuts, minimizing waste and rework.

2. Shaping and Molding Tools After cutting, the frames may require additional shaping or molding to create decorative elements or to ensure a perfect fit with the door panels. Advanced machines offer multiple shaping options to accommodate various design aesthetics.

3. Assembly Station Many door frame machines incorporate automated assembly processes, where components such as hinges, locks, and seals are integrated directly into the frame. This feature significantly speeds up the production time.

door frame making machine

4. Quality Control Systems Modern machines often include quality control mechanisms that monitor the production process. These systems check for dimensional accuracy and finish quality, ensuring that every frame meets the required standards.

The Benefits of Using a Door Frame Making Machine

The utilization of door frame making machines brings numerous benefits to manufacturers

1. Increased Production Speed Automation significantly reduces the time required to produce door frames. What once took hours can now be completed in a fraction of the time, allowing manufacturers to meet high-demand scenarios without compromising quality.

2. Consistency and Quality Automated systems provide consistent results, reducing the likelihood of human error. This leads to higher quality products with uniform specifications, which is crucial for both aesthetic and functional purposes.

3. Cost Efficiency Although the initial investment in a door frame making machine may be high, the long-term cost savings through decreased labor, reduced waste, and improved efficiency can be significant. As production speeds up, manufacturers can take on more projects simultaneously, ultimately increasing profitability.

4. Customization With advanced programming capabilities, manufacturers can easily switch between different frame designs and sizes. Customization options also allow businesses to cater to specific market needs, resulting in enhanced customer satisfaction.

Conclusion

The door frame making machine is a vital asset for any manufacturing facility aiming to improve productivity and efficiency. As technology continues to evolve, these machines will likely become even more sophisticated, offering new features and capabilities. For businesses in the construction and manufacturing sectors, investing in a door frame making machine can lead to substantial competitive advantages, ensuring they remain at the forefront of the industry while meeting the needs of an ever-evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025