door frame production machinery suppliers and manufacturers for efficient construction solutions

The Role of Door Frame Forming Machine Manufacturers in Modern Construction

In today's architectural landscape, efficiency and precision are paramount. As construction projects become more complex and demanding, the tools and machinery used to facilitate these projects must also evolve. One such critical tool in this domain is the door frame forming machine. Manufacturers of these machines are not just producing equipment; they are playing a vital role in enhancing productivity and ensuring quality in the construction industry.

Understanding Door Frame Forming Machines

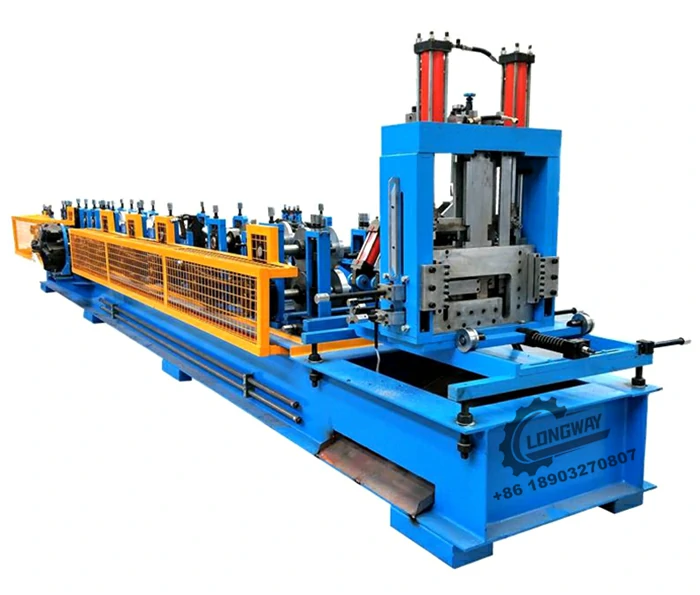

A door frame forming machine is an advanced piece of equipment that automates the process of shaping and assembling door frames. These machines can create various designs and sizes, accommodating the diverse needs of manufacturers in the construction sector. The primary function of these machines is to craft frames from materials such as steel, aluminum, or wood, ensuring that they are both sturdy and aesthetically pleasing.

The significance of door frame forming machines stems from their ability to enhance precision in manufacturing. Traditional methods of producing door frames can be labor-intensive and prone to human error. In contrast, automated machines provide consistent results, minimizing waste and maximizing productivity. This not only saves time but also contributes to cost efficiency in large-scale projects.

Key Benefits of Utilizing Door Frame Forming Machines

1. Increased Efficiency One of the most significant advantages of using a door frame forming machine is the substantial increase in production speed. With automation, manufacturers can produce a higher volume of door frames in a shorter timeframe. This efficiency is particularly beneficial for large construction projects that require a timely supply of materials.

2. Cost-Effectiveness By streamlining the manufacturing process, door frame forming machines reduce labor costs and material wastage. Manufacturers can optimize their production lines, leading to increased profit margins without compromising on quality. This cost-efficiency is crucial for contractors who must adhere to tight budgets.

door frame forming machine manufacturer

3. Customization Options Modern door frame forming machines offer a range of customization features. Manufacturers can tailor their products to meet specific specifications, catering to varying architectural designs and client preferences. This flexibility allows for more creative freedom, enabling builders to innovate and differentiate themselves in a competitive market.

4. Improved Quality Control Quality is a critical factor in construction. Door frame forming machines utilize precision engineering and high-quality materials, ensuring that each frame meets stringent standards. This reduces the likelihood of defects and ensures that installed frames not only fit perfectly but also withstand the test of time.

5. Sustainability As the construction industry moves towards more sustainable practices, door frame forming machine manufacturers are also integrating eco-friendly technologies into their operations. These machines can optimize material usage and reduce energy consumption, contributing to greener building practices. Manufacturers can source materials that are recyclable or sustainably sourced, aligning with global sustainability goals.

The Future of Door Frame Forming Machines

As technology continues to advance, the future of door frame forming machines looks promising. Innovations such as artificial intelligence, machine learning, and IoT (Internet of Things) are likely to further enhance the capabilities of these machines. For example, AI can optimize production processes, while IoT can facilitate real-time monitoring and maintenance, ensuring machines operate at peak performance.

Moreover, as construction techniques evolve, manufacturers are expected to adapt their machines to accommodate new materials and design trends. This adaptability is essential as architects and builders increasingly seek unique and advanced solutions for their projects.

Conclusion

In conclusion, door frame forming machine manufacturers are integral to the construction industry's evolution. By producing efficient, cost-effective, and high-quality machines, these manufacturers empower builders to meet the demands of modern construction. The benefits of using such machines—ranging from increased efficiency and customization to improved quality and sustainability—underscore their importance in contemporary architecture. As we move forward, embracing technological advancements will unlock even greater potential in the manufacturing processes related to door frames, ensuring that the industry continues to thrive and innovate.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025