decking panel roll forming machine

The Advancements in Decking Panel Roll Forming Machines

In recent years, the construction industry has witnessed a significant transformation driven by technological advancements. Among these innovations, decking panel roll forming machines have emerged as essential equipment in the production of high-quality metal decking panels. These machines not only enhance efficiency but also ensure precision in manufacturing, catering to the rising demand for durable and aesthetically pleasing building materials.

Understanding Decking Panels

Decking panels are structural components used in various applications, including flooring, roofing, and wall systems. They offer significant advantages such as strength, lightweight properties, and resistance to environmental factors. Typically made from materials like steel or aluminum, these panels are designed to bear heavy loads while providing a stable and secure platform. As construction projects evolve, the demand for customized, high-strength decking panels continues to grow, thus driving the need for advanced manufacturing technologies such as roll forming.

The Role of Roll Forming Technology

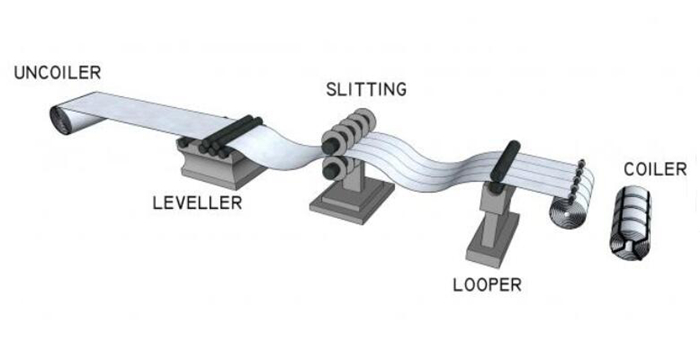

Roll forming is a process that involves feeding a continuous strip of metal through a series of rollers, which gradually shape the material into the desired profile. This method is particularly advantageous for producing decking panels as it allows for high-speed production, minimal waste, and cost-effectiveness. The roll forming machines are equipped with multiple sets of rollers, each designed to perform a specific task in the shaping process. This ensures that the final product has uniform dimensions and superior quality.

Key Features of Decking Panel Roll Forming Machines

Modern decking panel roll forming machines come with a variety of features that enhance their performance and usability

1. Automated Control Systems Most machines are equipped with advanced control systems that allow operators to set the parameters for production runs easily. This automation reduces human error and increases efficiency.

2. Quick Changeover Many roll forming machines now feature a quick-change mechanism that allows for the rapid swapping of tooling. This flexibility is critical for manufacturers who need to produce different profiles or adapt to changing market demands swiftly.

decking panel roll forming machine

3. High-Speed Production With advancements in technology, contemporary machines can operate at high speeds without compromising the quality of the output. This capability significantly boosts productivity and reduces lead times.

4. Quality Assurance Features Integrated quality control systems can monitor the thickness, width, and profile of the panels during production. These features help ensure that all products meet the stringent standards required in the construction industry.

Applications of Decking Panels

The versatility of decking panels manufactured through roll forming technology is evident in their wide range of applications. They are commonly used in

1. Commercial Buildings Decking panels are crucial in constructing floors and roofs in warehouses, shopping centers, and office buildings due to their strength and durability.

2. Residential Projects Homebuilders increasingly utilize metal decking panels for garages, sheds, and outdoor spaces because of their aesthetic appeal and longevity.

3. Infrastructure In civil engineering, decking panels are employed in bridges and elevated walkways, offering a lightweight yet sturdy option for construction projects.

The Future of Decking Panel Roll Forming Machines

Looking ahead, the future of decking panel roll forming machines appears bright. As construction materials and standards continue to evolve, manufacturers will need to adapt quickly to remain competitive. Innovations such as smart technology integration, where machines can provide real-time data and analytics, are on the horizon. Additionally, the push towards sustainable building practices will likely drive the development of machines capable of processing recycled materials.

In conclusion, decking panel roll forming machines play a crucial role in modern construction processes. Their ability to produce high-quality, customized panels efficiently positions them at the forefront of the industry. As technology continues to advance, these machines will undoubtedly contribute to shaping the future of construction materials, meeting the needs of both manufacturers and consumers alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025