Deck Floor Roll Forming Machine Supplier and Manufacturer for Quality Construction Solutions

The Role of Deck Floor Roll Forming Machines in Construction

In the competitive world of construction and manufacturing, efficiency and quality are paramount. One of the leading technologies that meet these demands is the deck floor roll forming machine. This specialized equipment is designed to produce metal decking components that are essential for various construction projects, particularly in the creation of floors and roofs in commercial and residential buildings. This article delves into the significance of these machines, their manufacturing process, and the benefits they offer to industry professionals.

Understanding Deck Floor Roll Forming Machines

Deck floor roll forming machines are heavy-duty pieces of equipment used to produce metal decking profiles from sheets of metal. These machines are designed to take metal coils as input and convert them into desired deck profiles through a continuous rolling and forming process. The resultant products are typically used as floors and ceilings in multi-story buildings and are commonly made from materials such as steel or aluminum.

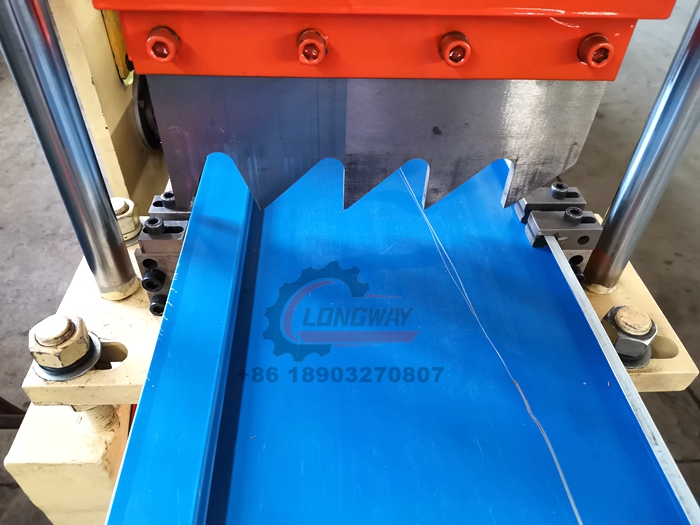

The machine operates on the principle of continuous forming, where the metal sheet is passed through various rollers set in a specific configuration. Each roller gradually shapes the metal into the desired profile, ensuring precision and uniformity. The entire process is both automated and efficient, allowing manufacturers to produce large quantities of metal decking with minimal human intervention.

The Manufacturing Process

The manufacturing process of deck floor roll forming machines involves several critical steps. Initially, high-quality metal coils are fed into the machine. As the coils enter, they are continuously fed into a series of rollers that shape the metal into the specified profile. The design of the rollers is crucial as it determines the final shape and thickness of the deck panels.

After the metal has been formed, it goes through a cutting station where it is cut to the required lengths. This cutting can be done either at predetermined lengths or by a manual or automated mechanism that measures the desired size. Once cut, the panels may undergo additional processes such as punching (for holes or slots) or coating (for corrosion resistance).

Quality control is integral throughout this process. Manufacturers often perform inspections at different stages to ensure that the finished product meets industry standards and customer specifications.

deck floor roll forming machine manufacturer

Advantages of Using Deck Floor Roll Forming Machines

1. Efficiency One of the most significant advantages of deck floor roll forming machines is their efficiency. These machines can produce large quantities of decking in a fraction of the time it would take using traditional methods. This allows manufacturers to meet tight deadlines and fulfill large orders.

2. Cost-Effectiveness By automating the production process, companies can save on labor costs. The ability to produce items quickly and with less waste also contributes to overall cost savings.

3. Quality and Precision Roll forming machines can maintain tight tolerances, ensuring that the panels produced are consistent in quality. This precision is crucial in construction, where structural integrity is vital.

4. Versatility Deck floor roll forming machines can produce a variety of decking profiles and sizes, making them suitable for various projects. This versatility allows manufacturers to cater to different customer needs effectively.

5. Durability The materials used in the production of deck panels, along with the efficient forming process, result in durable products that can withstand harsh environmental conditions, thus increasing the lifespan of the structures they are used in.

Conclusion

Deck floor roll forming machines play an essential role in the construction industry. Their ability to produce high-quality, durable, and cost-effective metal decking makes them a preferred choice for manufacturers and builders alike. As construction projects become more demanding and complex, the significance of these machines will only continue to grow. Companies looking to streamline their production processes and enhance the quality of their products would do well to invest in a reliable deck floor roll forming machine, thereby staying ahead in this competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025