High-Quality Deck Roll Former Manufacturers - Precision Engineered Solutions

Understanding Deck Roll Formers A Guide to Manufacturers and Their Offerings

Deck roll formers are essential machines in the construction and manufacturing industry, specifically designed to produce metal decking for various applications, including commercial and residential buildings. As the demand for quality construction materials grows, the importance of reliable deck roll former manufacturers has increased, leading to technological advancements and competitive offerings in the marketplace.

A deck roll former operates by taking flat metal sheets and progressively shaping them into desired profiles through a series of rollers. This process conveys the material through multiple stations, each refining its shape until it reaches the final deck profile. These machines can create various types of decking, including composite decking, structural steel decking, and form decking, each suited for different construction needs.

Understanding Deck Roll Formers A Guide to Manufacturers and Their Offerings

One key aspect to look for in a deck roll former manufacturer is the variety of decking profiles they can produce. A reputable manufacturer will offer a wide selection of roll-forming profiles, including standard and custom designs. This flexibility allows businesses to meet diverse client needs and adapt to evolving market demands. Additionally, advanced manufacturers often provide integrated solutions that may include auto-feed systems, PLC control systems, and other technological enhancements.

deck roll former manufacturers

Another critical factor is the manufacturer’s production capabilities. Leading companies often emphasize the efficiency of their machines, with some capable of producing thousands of linear meters of decking per hour. This efficiency not only meets high-volume production requirements but also reduces lead times, giving businesses a competitive edge.

Furthermore, customer support and service are vital considerations when selecting a manufacturer. A strong after-sales support system ensures that businesses can maintain their machinery effectively, minimizing downtime and repair costs. Reliable manufacturers often provide training for operators, maintenance services, and readily available spare parts to ensure the long-term functionality of their equipment.

Apart from quality and support, the reputation of the manufacturer plays a significant role. Many manufacturers have established their presence in the industry through positive customer reviews and a portfolio of successful installations. Engaging with existing clients of the manufacturer can provide insights into the machine's performance and overall satisfaction.

In conclusion, selecting the right deck roll former manufacturer is crucial for businesses looking to invest in metal decking production. It’s essential to evaluate the range of products offered, production capabilities, and the level of customer support available. By partnering with a reputable manufacturer, businesses can enhance their operational efficiency, product quality, and ultimately, their competitive position in the construction industry. As the market continues to evolve, staying informed about the latest advancements and offerings from various manufacturers will be key to success in this dynamic field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

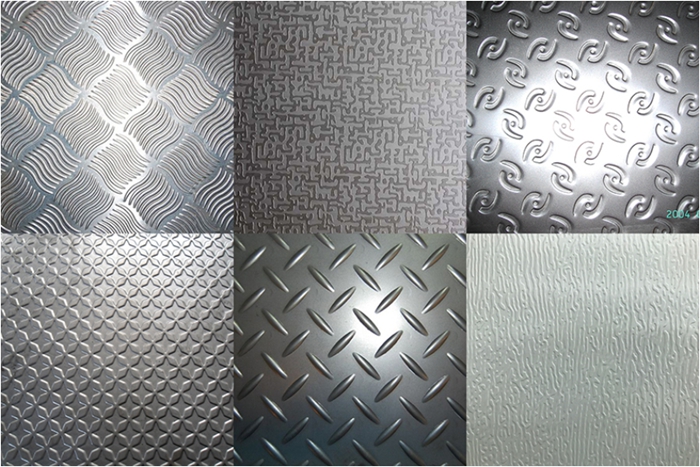

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025