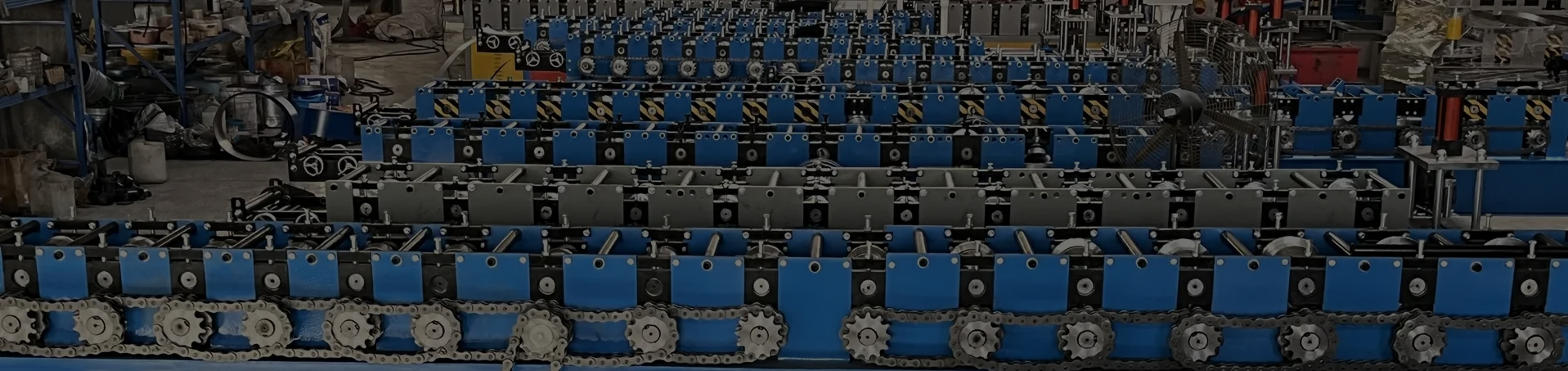

cz shaped purlin roll form machine

Understanding the CZ Shaped Purlin Roll Form Machine

In the modern construction industry, efficiency and precision are paramount. One of the key components in building frameworks is purlins, which serve as vital structural support for roofs and walls. The CZ shaped purlin roll form machine is a specialized apparatus designed to produce high-quality purlins in a cost-effective manner. This article explores the significance, working principle, advantages, and applications of the CZ shaped purlin roll form machine.

What is a CZ Shaped Purlin?

CZ shaped purlins are structural components that can take on a C or Z shape, hence the name. They are predominantly utilized in steel frame structures, providing excellent support for roofing and cladding. The design enables efficient load distribution and helps with fast installation. These purlins can be produced in various sizes and thicknesses to meet specific project needs.

The Functionality of the Roll Form Machine

The core function of the CZ shaped purlin roll form machine is to convert flat steel sheets into accurately shaped purlins through a continuous and automated process. The machine employs a roll forming technique, where the steel is passed through a series of rollers that gradually shape the material into the desired profile.

1. Feeding Section The process begins with the raw material, typically steel coils, being fed into the machine. The feeding mechanism ensures a steady supply of steel for shaping.

2. Roll Forming Section As the steel continues to pass through the machine, it goes through a series of pre-designed rollers. Each roller progressively bends the steel into the final CZ shape. This step is crucial, as it requires precise alignment and the correct angle of bending to achieve the desired profile.

3. Cutting Section Once the steel has taken on the appropriate shape, it reaches the cutting section. Here, the purlin is cut to the specified lengths, ready for use in construction projects.

4. Output Section Finally, the finished purlins are stacked and prepared for transportation.

Advantages of CZ Shaped Purlin Roll Form Machines

The adoption of CZ shaped purlin roll form machines brings numerous advantages to the construction industry

cz shaped purlin roll form machine

- Cost Efficiency The ability to produce purlins on-site significantly reduces material waste and minimizes transportation costs

. Bulk production also lowers labor costs.- High Precision The automated nature of the roll forming process ensures that each purlin is produced with consistent quality and dimensions, reducing the chances of errors often associated with manual fabrication.

- Flexibility Operators can easily adjust the machine settings to create purlins of varying sizes and shapes, catering to different construction needs without requiring extensive retooling.

- Speed Roll forming is a continuous process that can produce a large number of purlins in a short time, facilitating faster project completion.

- Durability The CZ shape offers strength and stability, making these purlins ideal for various environmental conditions and structural loads.

Applications of CZ Shaped Purlins

The versatility of CZ shaped purlins makes them suitable for a wide range of applications

1. Commercial Buildings They are extensively used in the construction of warehouses, factories, and retail outlets, providing robust support for roofs and walls.

2. Residential Structures Increasingly popular in residential construction, CZ purlins offer a reliable solution for roof support in homes.

3. Agricultural Buildings Their strength and lightweight nature make them ideal for barns and storage facilities.

4. Industrial Applications CZ purlins are often utilized in manufacturing plants and workshops where heavy loads need to be supported.

In conclusion, the CZ shaped purlin roll form machine is a pivotal tool in the construction industry. Its ability to produce high-quality purlins efficiently and cost-effectively supports the evolving demands of architecture and engineering. As technology continues to advance, these machines will likely become even more sophisticated, further enhancing their utility in modern construction practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025