c&z purlin roll forming machine

Understanding C & Z Purlin Roll Forming Machines

In the world of construction and manufacturing, efficiency and precision are paramount. One of the critical components used in building structures is purlins, which are horizontal beams that support roofs and walls. Among the most common types are C and Z purlins, which are named after their shapes. The production of these purlins is facilitated through specialized equipment known as roll forming machines, specifically C & Z purlin roll forming machines. This article delves into their design, functionality, benefits, and applications.

What Are C and Z Purlins?

C and Z purlins are structural steel components used extensively in the building industry. C-purlins have a 'C' shaped cross-section, while Z-purlins feature a 'Z' shape. These shapes provide distinct advantages C-purlins are often used for support roles, attaching ceil ceilings, while Z-purlins can be overlapped, offering enhanced structural continuity and load bearing capabilities. Their light weight yet strong structure makes them ideal for various applications, from warehouses to agricultural buildings.

The Importance of Roll Forming Machines

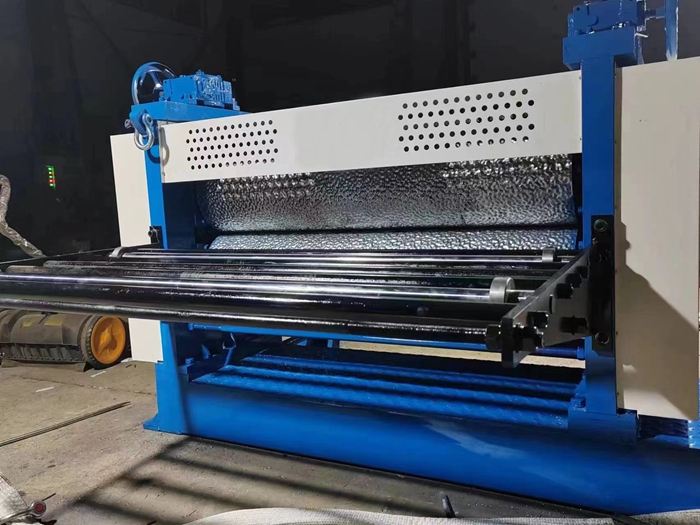

Roll forming is a continuous bending operation in which long strips of metal, typically steel or aluminum, are passed through consecutive pairs of rolls to gradually shape the material. C & Z purlin roll forming machines are specifically designed to produce these purlin profiles at high speeds and with exceptional accuracy.

These machines can be fully automated, allowing for quick adjustments to produce various sizes and shapes of purlins. This adaptability is crucial in meeting the industry's diverse demands without needing multiple machines. The typical components of a roll forming machine include a decoiler, feed mechanism, forming rollers, cutting mechanism, and a control system that ensures precision operation.

Advantages of C & Z Purlin Roll Forming Machines

1. Efficiency One of the most significant benefits of using roll forming machines is their high production efficiency. These machines can produce long lengths of purlins in one continuous run, significantly reducing labor costs and time.

c&z purlin roll forming machine

2. Cost-Effectiveness Though the initial investment in a roll forming machine can be substantial, the long-term savings in labor and raw material waste generally justify the expense. The machines are designed to optimize material usage, minimizing scrap and maximizing output.

3. Quality and Consistency The automated processes involved in roll forming lead to enhanced product quality. The precision of the machines ensures that purlins are produced to exact specifications, providing consistent quality throughout the manufacturing process.

4. Versatility Modern C & Z purlin roll forming machines can be easily adjusted to produce various sizes and thicknesses of purlins, allowing manufacturers to diversify their product offerings without investing in additional equipment.

5. Durability The purlins produced are not only lightweight but also possess high strength, making them suitable for load-bearing applications without the risk of bending or warping.

Applications of C and Z Purlins

C and Z purlins are used in numerous applications across various industries. They are commonly found in

- Construction Providing support for roofs and walls in commercial, industrial, and residential buildings. - Agriculture Creating strong, reliable structures for barns, livestock buildings, and storage facilities. - Transportation Used in the construction of warehouses and shipping facilities to support large roofs. - Infrastructure Vital in creating frameworks for bridges, airports, and other large-scale infrastructure projects.

Conclusion

C & Z purlin roll forming machines are indispensable tools in modern construction and manufacturing. They enable the efficient production of high-quality purlins that can meet the diverse demands of various industries. With advancements in technology, these machines continue to evolve, offering greater speed, precision, and versatility, ensuring they remain a vital component in the construction supply chain. As industries grow and adapt, the reliability and efficiency of C & Z purlin roll forming machines will undoubtedly play a crucial role in shaping our built environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025