C-Channel and Z-Channel Purlin Metal Roll Forming Equipment for Efficient Production

Understanding C/Z Purlin Metal Roll Forming Machines

In the realm of modern construction and manufacturing, efficiency and precision are paramount. Among the various tools and machines that facilitate these attributes, the C/Z purlin metal roll forming machine stands out as a critical asset. This machine is specifically designed to produce high-quality C and Z purlins, which are essential components in steel structures. This article explores the functionality, benefits, and applications of these machines.

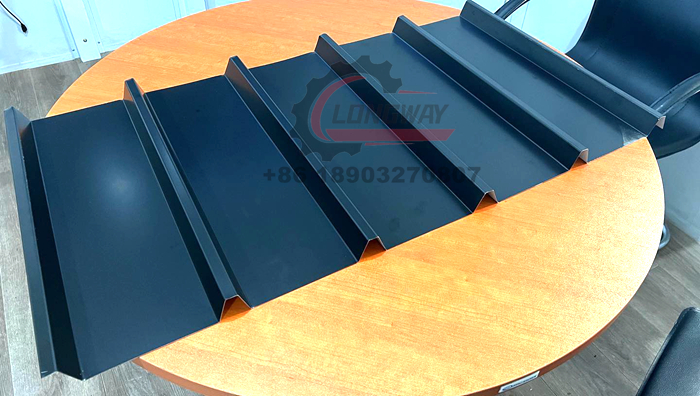

What are C and Z Purlins?

Purlins are structural members used to support roofs and walls in buildings. The terms C and Z refer to the cross-sectional shapes of the purlins. C purlins have a C shaped profile, while Z purlins have a Z shaped profile. Both types are crucial in building frameworks, providing stability and strength. Their design allows for easy stacking and spacing, which is essential in creating robust support systems for various structures, including warehouses, factories, and agricultural buildings.

How C/Z Purlin Metal Roll Forming Machines Work

The C/Z purlin metal roll forming machine operates through a continuous process of feeding a metal coil, usually made of galvanized steel, through a series of rollers. These rollers gradually shape the flat metal into a C or Z profile. The key stages of this process include

1. Material Feeding The raw metal coil is fed into the machine, where it is unwound and straightened. 2. Roll Forming A series of rollers are strategically placed to gradually transform the metal into the desired profile. Each roller applies pressure, shaping the metal without cutting it. 3. Cutting Once the desired length is achieved, the machine utilizes a cutting mechanism to produce the finished purlin. 4. Output The finished C or Z purlins are then ejected for stacking or further processing.

This continuous production process is highly automated, enhancing efficiency and allowing for large-scale output.

c/z purlin metal roll forming machine

Benefits of C/Z Purlin Metal Roll Forming Machines

1. Efficiency These machines are capable of producing purlins at a rapid rate, significantly reducing manufacturing time compared to traditional methods. 2. Consistency The automated nature of roll forming ensures that each purlin is produced with a consistent quality and accuracy, reducing material wastage and labor costs. 3. Versatility Many C/Z purlin metal roll forming machines can be adjusted to produce different sizes and shapes, catering to various project requirements without the need for extensive reconfiguration. 4. Durability The use of high-quality steel in the production of purlins ensures that the final products are strong and long-lasting, capable of withstanding environmental challenges.

Applications of C/Z Purlin Metal Roll Forming Machines

C and Z purlins are applied extensively in construction and infrastructure projects. Some common applications include

- Roofing Systems Purlins provide essential support for roofs, often used in conjunction with other materials for enhanced strength and durability. - Wall Support In building structures, Z purlins are often utilized as wall support, providing the necessary framework for cladding materials. - Industrial Sheds Purlins are pivotal in the design and construction of industrial sheds and warehouses, offering the required structural integrity. - Agricultural Buildings Many agricultural buildings leverage the benefits of C and Z purlins, providing reliable support for equipment and storage.

Conclusion

C/Z purlin metal roll forming machines have revolutionized the way purlins are manufactured in the construction industry. Their efficiency, versatility, and precision not only streamline production processes but also contribute to constructing durable and robust structures. As the demand for steel buildings continues to grow, the significance of these machines in meeting that demand cannot be overstated. Investing in high-quality C/Z purlin roll forming machines is an investment in the future of construction, ensuring that projects are completed on time, within budget, and to a high standard of quality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025