Top Suppliers for C Z Purlin Forming Machines in the Industry Today

Understanding C/Z Purlin Forming Machines A Comprehensive Overview

In the realm of modern construction and infrastructure, the efficient use of materials and technology plays a pivotal role. One such innovation is the C/Z purlin forming machine, a sophisticated piece of equipment widely utilized in the fabrication of purlins, which are critical components in steel structures. This article explores the significance of C/Z purlin forming machines, their advantages, and what to consider when selecting a supplier.

What Are C/Z Purlins?

C/Z purlins are horizontal structural members used to support roof and wall sheeting on buildings. They can be made from various materials but are predominantly crafted from steel for durability and strength. The C and Z nomenclature refers to the shape of the purlin's cross-section. C purlins are suitable for structures with lower loads and are typically installed vertically, while Z purlins are used for heavier loads and may be installed horizontally or vertically.

The Importance of C/Z Purlin Forming Machines

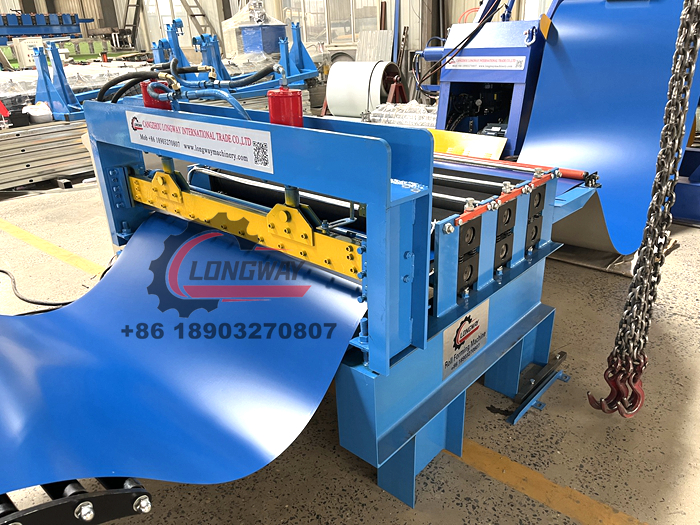

C/Z purlin forming machines are designed to fabricate these purlins efficiently and accurately. They work through a rollforming process that involves feeding steel coils into the machine, which continuously molds the material into purlin shapes using a series of rolls. This automation not only speeds up the production process but also ensures consistent quality and precision, essential for meeting stringent construction standards.

Key Advantages of Using C/Z Purlin Forming Machines

1. Cost-Effectiveness By producing purlins on-site, businesses can significantly reduce material waste and labor costs. Furthermore, bulk production capabilities lower the cost per unit, making it an economical choice for construction projects.

2. Customization Different projects have unique requirements. C/Z purlin forming machines allow for customization in terms of dimensions and thickness. This flexibility enables manufacturers to cater to specific needs, enhancing overall project effectiveness.

3. Durability and Strength Since these machines produce purlins from high-quality steel, the end products boast superior strength and durability. This ensures long-lasting performance, reducing the need for frequent repairs or replacements.

4. High Production Efficiency C/Z purlin forming machines can produce large quantities of purlins in a relatively short period. This efficiency is crucial for meeting tight deadlines in construction projects.

c z purlin forming machine supplier

5. Ease of Operation Most modern forming machines come equipped with user-friendly interfaces and automation technology, making them easy to operate. This reduces the training time required for new staff, helping businesses maintain productivity.

Choosing the Right Supplier

When it comes to procuring a C/Z purlin forming machine, selecting the right supplier is just as important as the machine's specifications. Here are some key factors to consider

1. Reputation and Experience Look for suppliers with a proven track record in the industry. Established manufacturers are likely to have experience in creating reliable, high-quality machines, and they often provide customer testimonials to verify their claims.

2. Product Range A good supplier should offer a variety of machines and customization options to cater to different needs. This includes machines with varying capacities, features, and designs.

3. After-Sales Support Reliable after-sales support is crucial. This includes technical assistance, spare parts availability, and warranty services. Ensure that the supplier provides adequate support to address any issues that may arise post-purchase.

4. Quality Assurance Ensure the machines comply with industry standards and undergo rigorous quality checks during manufacturing. Certification and compliance with international standards can serve as a good indicator of quality.

5. Pricing While it’s important to find a cost-effective solution, be cautious of prices that seem too good to be true. Quality should be prioritized over saving a few dollars, as poor-quality machines can lead to long-term financial loss.

Conclusion

C/Z purlin forming machines are vital in the modern construction landscape, enabling manufacturers to produce high-quality, durable purlins efficiently and cost-effectively. By understanding the functionalities and advantages of these machines, along with careful consideration when selecting a supplier, businesses can significantly enhance their construction processes, ensuring structural integrity and long-term success in their projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025