c z purlin forming machine

The Importance of C-Z Purlin Forming Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency, accuracy, and cost-effectiveness are paramount. One of the machines that embodies these requirements is the C-Z purlin forming machine. This specialized equipment is designed to produce structural components that are essential in the construction industry, particularly for roof and wall systems in metal buildings. Understanding the functionality and benefits of C-Z purlin forming machines reveals why they are crucial in today's manufacturing landscape.

Understanding C-Z Purlin Profile

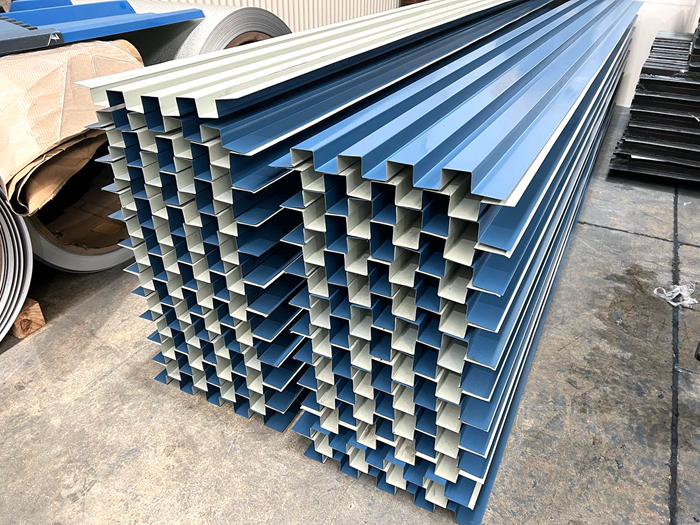

C and Z purlins are steel members used in the framework of structures. They come in different profiles, with C purlins featuring a C-shaped cross-section and Z purlins shaped in a Z profile. These components are pivotal in providing support and stability to roofing systems, sheds, warehouses, and other building types. The choice between C and Z profiles typically depends on specific design requirements and load considerations.

Working of C-Z Purlin Forming Machines

C-Z purlin forming machines are designed to convert raw materials, mainly galvanized steel, into precisely shaped purlins. The process begins with the feeding of steel coils into the machine. As the coil passes through various rollers, it undergoes a series of bending and shaping operations to achieve the desired cross-sectional shape. Advanced forming machines employ Internet of Things (IoT) technology for improved efficiency, allowing for real-time monitoring and adjustments during production.

These machines can produce purlins of varying thicknesses, lengths, and dimensions according to the specific needs of a project. They can handle multiple gauges of steel, making them versatile and adaptable to different construction requirements. Moreover, the ability to form purlins in different depths and sizes contributes to the overall structural integrity of buildings, leading to enhanced safety and durability.

Advantages of Using C-Z Purlin Forming Machines

c z purlin forming machine

The advantages of utilizing C-Z purlin forming machines extend beyond just production speed

. Here are some key benefits1. Cost-Efficiency By automating the manufacturing process, these machines significantly reduce labor costs and material waste. Efficient use of resources directly impacts the bottom line, enabling businesses to remain competitive in a challenging market.

2. Precision and Consistency The precision of C-Z purlin forming machines ensures that every purlin produced meets stringent quality standards. This consistency is vital for structural integrity and building safety.

3. Rapid Production With the ability to produce high volumes of purlins in a short amount of time, manufacturers can meet tight project deadlines without sacrificing quality.

4. Customizability Modern forming machines can be programmed for various specifications, allowing manufacturers to cater to specific client needs and preferences easily.

5. Durability and Quality Products manufactured using these machines are often made from high-quality materials that withstand weather elements, resulting in long-lasting structural components.

Conclusion

C-Z purlin forming machines represent a significant advancement in manufacturing technology. Their ability to steadily produce high-quality, precision-engineered components makes them invaluable to the construction industry. As the demand for steel structures continues to rise alongside urbanization and infrastructure development, the role of C-Z purlin forming machines will undoubtedly grow. By leveraging these machines, manufacturers ensure they can deliver efficient, reliable, and cost-effective solutions to meet the demands of a rapidly evolving market. In conclusion, investing in a C-Z purlin forming machine could prove to be a prudent decision for any business looking to enhance its production capabilities and improve its competitive edge.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025