C/Z Exchangeable Roll Forming Equipment for Versatile Metal Fabrication Solutions

Understanding C/Z Exchangeable Roll Forming Machines An Overview

In modern manufacturing, efficiencies and versatility are key to staying competitive. Among the myriad of technologies reshaping the industry, C/Z exchangeable roll forming machines have gained significant attention. These advanced machines provide a unique solution for producing various structural components, particularly in the construction and steel framing sectors. This article delves into the features, benefits, and applications of C/Z exchangeable roll forming machines.

What is Roll Forming?

Roll forming is a continuous bending process in which a long strip of metal, typically steel, is passed through a series of rollers that gradually shape it into a desired cross-section. This technique is widely used for producing metal parts with consistent shapes and lengths. Roll forming is particularly suitable for producing long lengths of items, making it an efficient option for various applications.

C/Z Exchangeable Roll Forming Machines

The C/Z exchangeable roll forming machine is specifically designed to produce C and Z sections, which are structural steel components widely used in commercial and industrial construction. These machines are equipped with specialized roll sets that can be quickly and easily exchanged, allowing manufacturers to switch between producing C-shaped and Z-shaped profiles without extensive downtime.

Key Features

1. Interchangeable Roll Sets The primary feature of C/Z roll forming machines is their ability to swap roll sets effortlessly. This design significantly reduces the time required for changeovers, enabling manufacturers to respond swiftly to varying production demands.

2. High Precision These machines are engineered for high precision, ensuring that the dimensions of the formed profiles meet stringent industry standards. This precision is crucial for structural applications where tolerance levels can impact overall project integrity.

3. Robust Construction Built from high-quality materials, C/Z exchangeable roll forming machines are designed to withstand the rigors of high-volume production. Their robust construction contributes to the longevity of the machinery, reducing maintenance costs and downtime.

4. User-Friendly Controls Modern C/Z roll forming machines come equipped with advanced control systems that allow operators to easily set parameters for speed, feeding, and cutting. User-friendly interfaces enhance operational efficiency, enabling any trained staff to run the machine effectively.

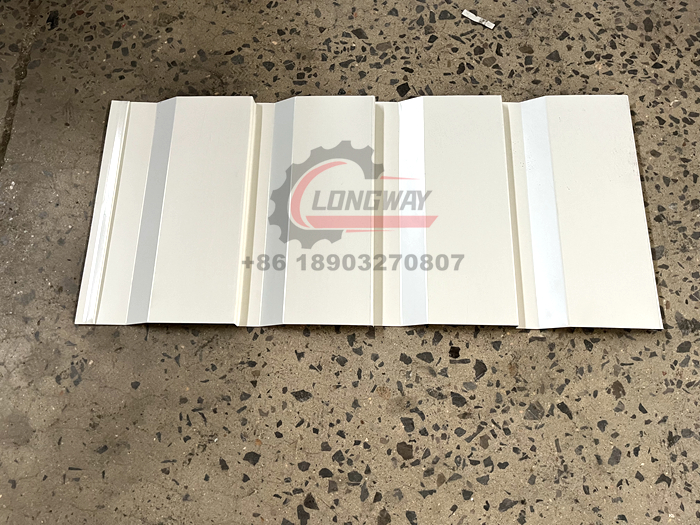

c/z exchangeable roll forming machine

5. Integration with Additional Equipment Many C/Z machines can be integrated with additional modules such as automatic stacking systems and CNC cutting tools. This integration further streamlines the production process and improves workflow efficiency.

Benefits of C/Z Exchangeable Roll Forming Machines

1. Versatility The ability to produce both C and Z section profiles with a single machine substantially increases manufacturing versatility. This flexibility is particularly advantageous for businesses that cater to multiple clients with varying requirements.

2. Cost-Effective By reducing the need for multiple machines, manufacturers can save on capital expenditure. The quick changeover capabilities also mean that production can be adjusted to meet demand without significant delays, enhancing overall profitability.

3. Space Efficiency With the capability to produce multiple profiles on one machine, businesses can utilize their factory floor space more efficiently, freeing up valuable area for other operations or additional machinery.

4. Faster Lead Times The efficiency inherent in C/Z exchangeable roll forming machines typically results in shorter lead times for production. Quicker turnarounds can significantly improve customer satisfaction and help businesses secure repeat contracts.

Applications

C/Z sections are pivotal in numerous applications, prominently in the construction of warehouses, industrial buildings, and commercial structures. They serve as essential components in framing systems, roof purlins, and wall girts. As these machines gain traction, their applications are expanding into other sectors including automotive, agriculture, and infrastructure development.

Conclusion

C/Z exchangeable roll forming machines represent a significant advancement in the field of metal forming technology. Their unique ability to produce varying structural profiles from a single machine not only enhances manufacturing efficiency but also allows companies to stay agile in a rapidly changing market. As businesses continue to seek ways to optimize production and reduce costs, the adoption of C/Z roll forming machines is likely to grow, solidifying their place as a vital asset in the modern manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025