cut to lenght line factories

The Importance of Cut-to-Length Line Factories in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. Among the various processes that contribute to these goals, cut-to-length (CTL) line factories play a critical role, especially in industries that involve metalworking, woodworking, and plastic fabrication. These specialized facilities are designed to convert raw materials into sized products through a streamlined process that enhances production capabilities and reduces waste.

Understanding Cut-to-Length Processing

Cut-to-length processing refers to the method of cutting long lengths of material, such as steel coils, sheets, or rolls, into specified shorter lengths to meet customer specifications. This process is particularly prevalent in industries where precision is essential, such as automotive, aerospace, and construction. Unlike traditional shearing or cutting methods that may lead to variability in size and quality, cut-to-length lines are designed to provide consistent and exact lengths, meeting stringent tolerance requirements.

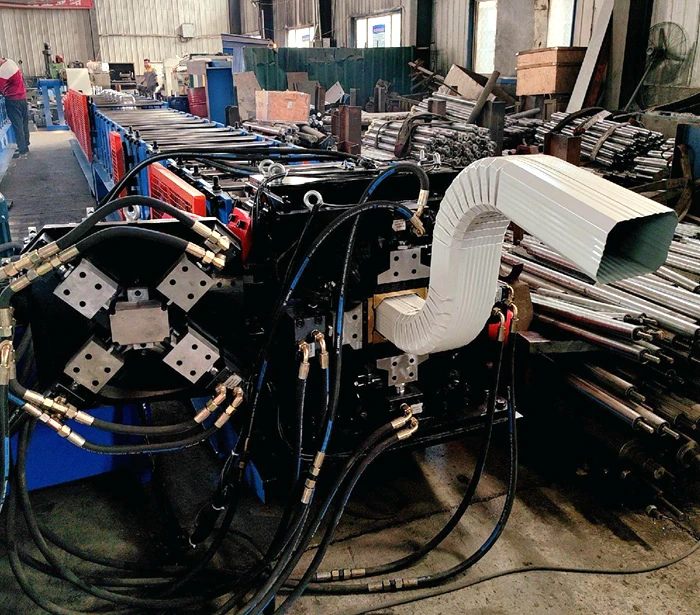

The Equipment Behind CTL Lines

At the heart of cut-to-length line factories are advanced machines that ensure efficiency and accuracy. A typical CTL line setup includes uncoilers, straighteners, and shearers. Uncoilers feed the raw material into the line, while straighteners eliminate any curvature or imperfections, preparing the material for cutting. The shearers then accurately cut the material to the desired lengths, which can be programmed and controlled with high precision. Many modern CTL lines are equipped with automation technologies and computer numerical control (CNC) to enhance operational efficiency and decrease human error.

Streamlined Operations and Production Efficiency

The integration of cut-to-length lines into manufacturing processes has drastically streamlined operations. By reducing the number of manual steps involved in cutting and measuring, CTL factories can significantly speed up production times. This is particularly advantageous for manufacturers who operate on tight deadlines or need to fulfill large orders. Additionally, the ability to quickly switch between different product sizes without extensive downtime allows manufacturers to respond to fluctuating customer demands more effectively.

cut to lenght line factories

Furthermore, by producing only the lengths required for specific applications, cut-to-length factories minimize material waste. This is not only beneficial from an environmental perspective but also contributes to overall cost savings. Less waste translates into lower operational costs, making CTL lines an economically viable solution for manufacturers looking to optimize their processes.

Quality Control and Customization

Aside from enhancing productivity, cut-to-length line factories also excel in maintaining consistent quality. The automated nature of these lines helps in achieving uniformity in product dimensions, which is critical for industries that require stringent quality assurance. With programmable systems, manufacturers can ensure that each cut adheres to the precise specifications laid out by clients, reducing the risk of defects.

Moreover, cut-to-length lines offer the flexibility needed for customization. Manufacturers can cater to a variety of customer needs, producing tailored lengths and specifications without compromising efficiency. This adaptability is particularly important in today’s market, where personalized products are becoming increasingly popular.

Challenges and Future Trends

While cut-to-length line factories bring numerous advantages, they are not without challenges. The initial investment in state-of-the-art machinery can be substantial, which may be a barrier for smaller manufacturers. Additionally, maintenance and operational training are vital to ensure that these advanced systems run smoothly.

Looking towards the future, the demand for cut-to-length line solutions is expected to grow. Innovations in technology, such as artificial intelligence and machine learning, are likely to enhance predictive maintenance and operational efficiency. As industries continue to evolve, cut-to-length factories will play an increasingly vital role in supporting manufacturers in meeting both current demands and future challenges.

In conclusion, cut-to-length line factories are essential components of modern manufacturing. They provide efficiency, precision, and customization in material processing, significantly contributing to the overall productivity of manufacturing operations. As these technologies advance, their impact on enhancing production capabilities will only grow, solidifying their importance in the industrial landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025