cut to lengh factories

The Significance of Cut-to-Length Factories in Modern Manufacturing

In the realm of manufacturing, efficiency and precision play crucial roles in determining the success of production processes. One of the specialized operations that has gained significant attention in recent years is cut-to-length (CTL) manufacturing. This process involves cutting raw materials, such as metal sheets or rolls, to specified lengths required by the customer, which allows manufacturers to optimize their output while reducing waste. As industries continue to evolve, cut-to-length factories are becoming increasingly important for various sectors, from automotive to construction.

What is Cut-to-Length Manufacturing?

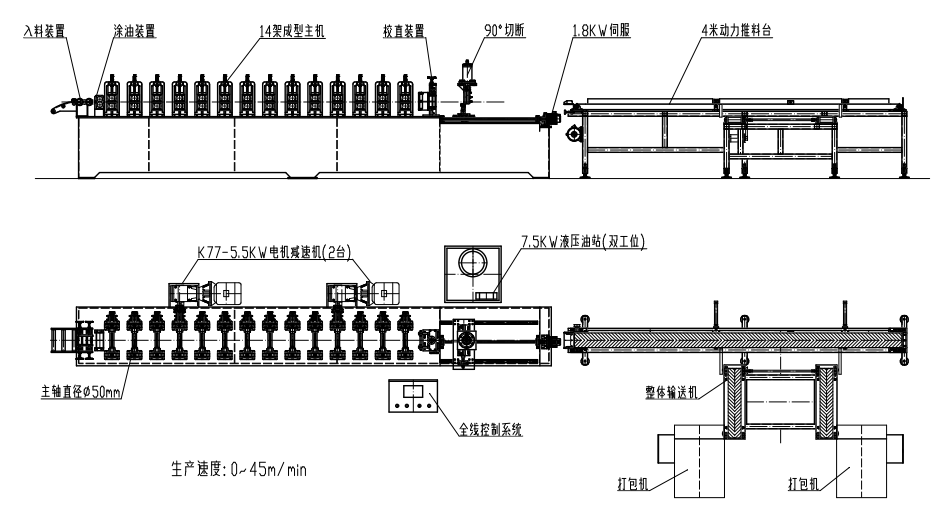

Cut-to-length manufacturing is a process where large rolls or sheets of material, such as steel or aluminum, are fed into machines that precisely cut them into sheets of predetermined lengths. This process is advantageous because it eliminates excessive handling and minimizes material wastage. Unlike traditional methods that may require additional processing steps, CTL operations streamline production by providing ready-to-use materials that can be directly delivered to manufacturers.

The cut-to-length process can involve several steps, including unrolling, leveling, cutting, and packaging. Each of these steps requires specialized machinery and skilled operators who ensure that the final products meet the required specifications and quality standards.

Advantages of Cut-to-Length Factories

1. Increased Efficiency One of the most significant advantages of cut-to-length factories is their ability to produce materials efficiently. By cutting materials to the exact lengths needed, manufacturers reduce the time and labor associated with processing raw materials. This efficiency is particularly beneficial in industries where speed and adaptability are critical.

2. Cost Reduction CTL operations can lead to substantial cost savings. By minimizing waste and improving material yield, manufacturers can lower their overall production costs. Additionally, cut-to-length factories often operate with a lean approach, reducing the need for excessive inventory and storage costs.

3. Customization In today’s competitive market, customization is essential. Cut-to-length factories can quickly adapt to changing customer demands by varying the lengths and dimensions of the cut materials. This flexibility not only meets the specific needs of clients but also enables manufacturers to respond promptly to market trends.

4. Quality Control Advanced cutting technologies used in CTL factories, such as laser and plasma cutting, enhance the precision of cuts, ensuring high-quality outputs. Manufacturers benefit from consistent quality, leading to higher customer satisfaction and fewer rework or returns.

cut to lengh factories

5. Environmental Impact With a growing emphasis on sustainability, cut-to-length manufacturing aligns with efforts to reduce waste and promote eco-friendly practices. By optimizing material usage, these factories contribute to a more sustainable production model, minimizing their ecological footprint.

Applications of Cut-to-Length Manufacturing

Cut-to-length factories serve a variety of industries, each with unique requirements

- Automotive Industry Cut-to-length steel sheets are used in the production of various vehicle components, reducing production time and ensuring that parts are cut to fit precisely within manufacturing specifications.

- Construction The construction industry relies heavily on CTL processes for beams, columns, and other structural components. Cut-to-length materials can significantly expedite the building process, ensuring that contractors receive exactly what they need for their projects.

- Aerospace Due to the high precision required in aerospace applications, CTL factories provide components that meet strict regulatory standards, ensuring safety and reliability in aircraft manufacturing.

- Consumer Goods Manufacturers of home appliances and furniture often require precise metal cuts, making CTL operations invaluable in producing components that fit seamlessly into finished products.

The Future of Cut-to-Length Factories

As technology continues to advance, the future of cut-to-length factories looks promising. Innovations such as automation, artificial intelligence, and real-time data analytics are set to enhance operational efficiency further. These technologies can help streamline processes, predict maintenance needs, and optimize inventory management.

In conclusion, cut-to-length factories are a pivotal aspect of modern manufacturing, driving efficiency, cost reduction, and quality control across various industries. As manufacturers strive to meet the demands of a rapidly evolving marketplace, the significance of CTL operations will only continue to grow. By embracing these processes, companies can enhance their competitive edge while contributing to a more sustainable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025