Cutting and Slitting Line Production for Precision Sheet Metal Processing Solutions

Understanding Slitting and Cut-to-Length Line Factories

In the manufacturing industry, efficiency and precision are paramount. Among the various processes used to convert raw materials into usable forms, slitting and cut-to-length (CTL) operations have gained significant prominence. These processes are especially prevalent in industries dealing with metals, plastics, and various sheet materials. This article delves into the functioning of slitting and cut-to-length line factories, exploring their significance, operational mechanisms, and benefits.

What is Slitting?

Slitting is a process of cutting large rolls of material into narrower strips. This method is extensively used in the production of metal coils, plastic sheets, and paper products. The slitting line typically consists of multiple components, including unwinding reels, slitting knives, guiding systems, and rewinders. The material is unwound from a large roll, guided through a set of rotating knives that slice it into the desired widths, and then rewound into smaller rolls.

The precision of the slitting process is crucial; it not only affects the quality of the final product but also influences operational efficiency. Modern slitting lines often utilize advanced technology, such as computer numerical control (CNC), to ensure precise cuts and consistent widths.

What is Cut-to-Length?

Cut-to-length, on the other hand, involves cutting a roll of material into fixed-length pieces. This process is particularly useful for industries requiring specific lengths of raw materials for manufacturing purposes. The CTL line operates by unwinding the material, measuring the precise length needed, and cutting it to size before stacking or bundling the finished pieces.

The CTL process allows manufacturers to provide products customized to their clients’ specifications, minimizing waste and ensuring that clients receive exactly what they need for their production processes.

The Significance of Slitting and CTL Lines

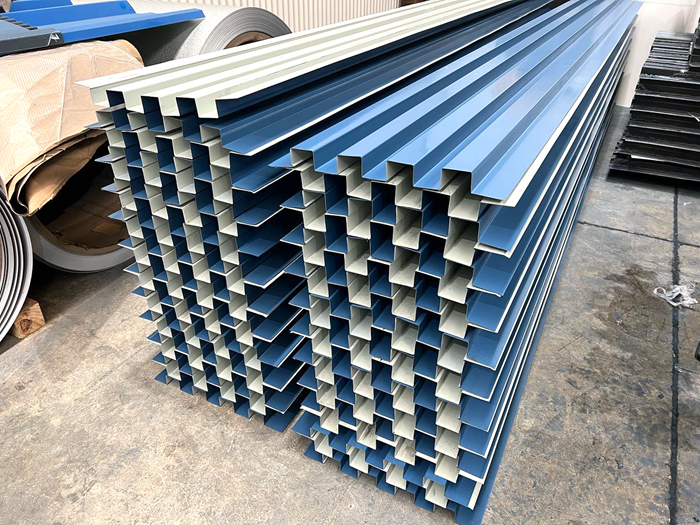

slitting and cut to length line factory

Slitting and cut-to-length lines hold significant importance in various manufacturing sectors. Firstly, they streamline the production process, enabling manufacturers to work seamlessly with large volumes of material. Instead of handling bulk rolls, businesses can produce smaller, easier-to-handle sheets or strips, improving overall workflow efficiency.

Secondly, these operations allow for material optimization. By cutting materials into the required sizes, manufacturers can significantly reduce waste. This not only cuts costs but also supports sustainable practices by making the most of available resources.

Moreover, the ability to customize products according to customer specifications enhances client satisfaction. Industries, from automotive to construction, often require materials in specific sizes, and having a flexible slitting and CTL system allows manufacturers to meet these needs effectively.

Investing in Technology

The advancement of technology has greatly influenced how slitting and cut-to-length lines operate. Modern machines are equipped with automated features that ensure accurate cuts, reduce manual labor, and increase production speeds. Integrating automation and data analytics into these processes allows for real-time monitoring and adjustment, leading to enhanced product quality and reduced downtime.

Furthermore, advancements in blade technology, such as coated and high-speed steel blades, have improved cutting efficiency, allowing for faster operations and longer service life.

Conclusion

In conclusion, slitting and cut-to-length line factories play a pivotal role in the manufacturing landscape, enabling companies to convert raw materials into precisely cut products efficiently and sustainably. As technology continues to evolve, the capabilities of these processes will undoubtedly expand, making them even more crucial in meeting the dynamic needs of various industries. Investing in state-of-the-art slitting and CTL lines is a strategic move for manufacturers aiming to enhance productivity, reduce waste, and satisfy customer demands.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025