Custom Roll Forming Machine for Trapezoidal Sheet Manufacturing and Design Solutions

Custom Trapezoidal Sheet Roll Forming Machine Revolutionizing Sheet Metal Production

In the ever-evolving world of manufacturing, efficiency and precision are paramount. One significant advancement in this arena is the custom trapezoidal sheet roll forming machine. This innovative equipment has transformed the way trapezoidal sheets—known for their strength and versatility—are produced, catering to various industries ranging from construction to manufacturing.

The trapezoidal sheet, characterized by its unique shape and interlocking design, offers excellent durability and is commonly used in roofing, cladding, and flooring applications. A roll forming machine is specifically engineered to convert flat sheets of metal into these predefined shapes using a continuous bending process. With a custom trapezoidal sheet roll forming machine, manufacturers can achieve higher production rates and improved material utilization.

One of the standout features of these machines is their ability to be tailored to specific production needs. By customizing the roll forming equipment, manufacturers can create trapezoidal sheets of different sizes, gauges, and materials, thus optimizing their production lines for various applications. This flexibility not only enhances productivity but also allows businesses to respond more swiftly to market demands, producing bespoke products that meet customer specifications.

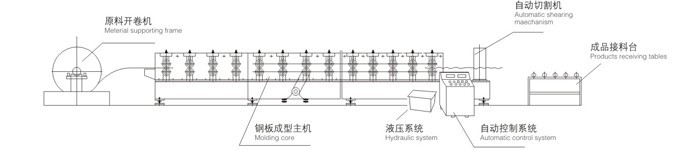

custom trapezoidal sheet roll forming machine

Moreover, the precision offered by modern roll forming machines reduces wastage, contributing to more sustainable manufacturing practices. With advancements in automation and CNC technology, these machines ensure consistent quality and dimensional accuracy, minimizing errors that could lead to costly rework. As a result, companies can significantly enhance their competitive edge by delivering high-quality trapezoidal sheets in a timely manner.

The installation of custom trapezoidal sheet roll forming machines also entails reduced labor costs and increased safety. Automation streamlines operations, allowing fewer workers to oversee the production processes while maintaining high levels of output. Furthermore, safety features integrated into these machines enhance workplace safety, reducing the likelihood of accidents.

In conclusion, custom trapezoidal sheet roll forming machines represent a significant advancement in sheet metal production. Their ability to deliver tailored solutions, coupled with improved efficiency, sustainability, and safety, makes them an invaluable asset for manufacturers. As industries continue to innovate, embracing such technology will be critical for maintaining competitiveness and meeting the growing demand for high-quality metal products.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025