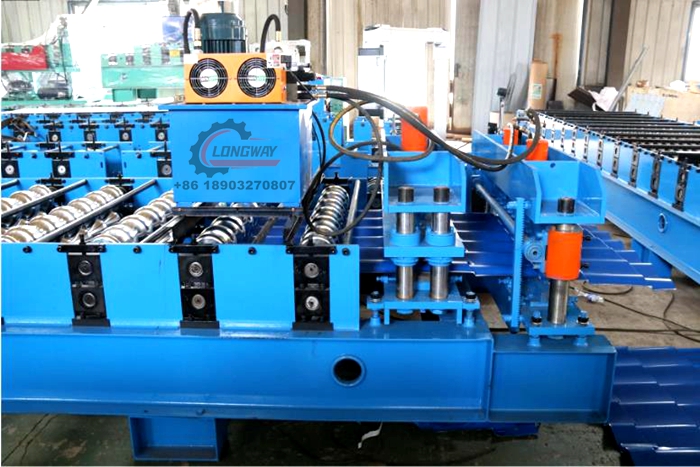

Custom Track Roll Forming Equipment for Precision Manufacturing Solutions

Custom Track Roll Forming Machine Revolutionizing Metal Fabrication

In the realm of metal fabrication, efficiency and precision are paramount. One of the innovations that have significantly contributed to these aspects is the custom track roll forming machine. This advanced machinery is designed to produce complex shapes and profiles from metal strips with exceptional accuracy, making it a vital tool in various industries ranging from construction to automotive.

At its core, a roll forming machine operates by feeding a flat metal strip through a series of rollers that progressively shape it into the desired cross-section. The custom track roll forming machine takes this process a step further, allowing manufacturers to create tailored profiles that meet specific requirements. This customization capability is crucial for businesses seeking to optimize their production processes and reduce material waste.

One of the standout features of custom track roll forming machines is their versatility

. These machines can be modified to produce a wide range of products, including tracks for sliding doors, window frames, and even complex structural components for buildings. The ability to design and produce unique profiles means that companies can cater to niche markets and develop products that stand out in a competitive landscape.Furthermore, the precision of roll forming technology ensures that each piece produced is consistent and high-quality. This reliability is crucial, especially in industries like automotive manufacturing where tolerances are critical. A custom track roll forming machine can maintain tight tolerances throughout long production runs, thereby enhancing the overall quality of the finished products.

custom track roll forming machine

Another significant advantage of these machines is their efficiency. Traditional metal fabrication methods often involve several steps, including cutting, bending, and welding, which can be time-consuming and labor-intensive. However, a roll forming machine streamlines this process by performing multiple operations in a single pass. This not only speeds up production times but also reduces labor costs, making it an attractive option for manufacturers aiming to improve their bottom line.

Moreover, the structure of the custom track roll forming machine allows for the use of a variety of materials, including steel, aluminum, and even high-strength alloys. This adaptability opens up new possibilities for product development, enabling companies to experiment with different materials and designs based on their specific needs and market demands.

In addition to its manufacturing benefits, investing in a custom track roll forming machine can lead to significant cost savings in the long run. By producing parts in-house, companies can cut down on outsourcing costs and have greater control over their supply chain. This also allows for faster response times to market changes, enabling businesses to stay agile in an ever-evolving industry.

In conclusion, the custom track roll forming machine represents a significant advancement in metal fabrication technology. With its ability to produce customized profiles, maintain high precision, and improve efficiency, it is an invaluable asset for manufacturers looking to enhance their production capabilities. As industries continue to demand greater innovation and adaptability, these machines will undoubtedly play a pivotal role in shaping the future of metalworking.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025