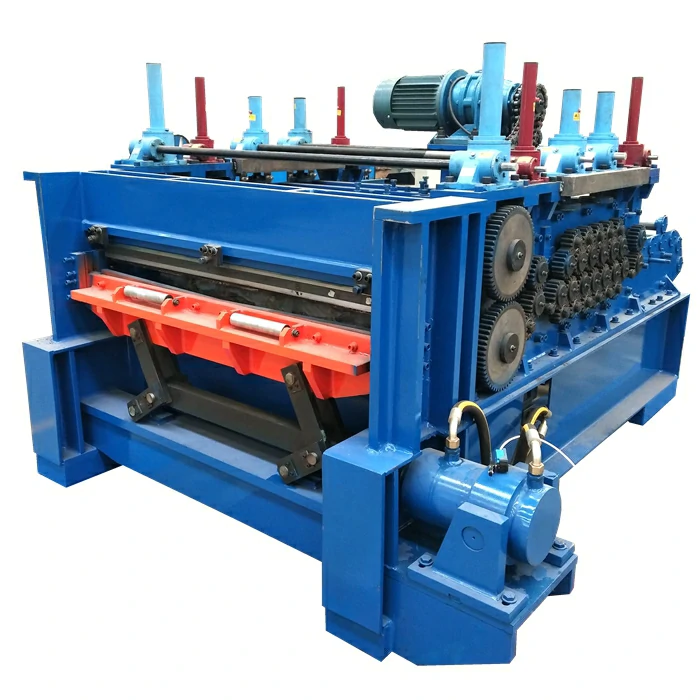

Customizable Track Roll Forming Equipment for Precision Manufacturing Solutions

Custom Track Roll Forming Machines Revolutionizing Manufacturing

In the rapidly evolving landscape of manufacturing, efficiency and precision are key to staying competitive. Among the technology that has emerged to meet these demands is the custom track roll forming machine. This sophisticated piece of equipment is designed to create specific profiles and shapes from metal sheets, offering versatility and enhancing production capabilities in various industries.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of sheet metal is passed through a series of rollers that progressively shape the material into the desired profile. This process is particularly advantageous for producing long lengths of identical components, making it ideal for industries that require high-volume production with tight tolerances.

Custom track roll forming machines are specialized equipment that tailor the roll forming process to create specific track profiles used in applications such as railways, construction, and automotive sectors. These machines can produce tracks of varying sizes and shapes based on the unique requirements of each project, enabling manufacturers to meet both quality and design specifications.

The Benefits of Customization

One of the standout features of custom track roll forming machines is their ability to be tailored to specific production needs. Manufacturers can design the machine to produce tracks of various profiles, thicknesses, and lengths, facilitating greater flexibility in design and application. This customization not only streamlines production processes but also reduces waste by ensuring that only the needed materials are used.

Additionally, custom machines can integrate advanced technologies such as automated controls, sensors, and software for real-time monitoring. This integration contributes to higher precision and consistency, minimizing the chances of defects and enhancing overall quality.

Economic Efficiency

Investing in custom track roll forming machinery can lead to significant cost savings for manufacturers

. By optimizing the production process, companies can increase their output while reducing labor costs and material waste. The longevity and reliability of these machines underscore the one-time investment, leading to lower operational costs over time.custom track roll forming machine

Furthermore, because roll forming is a continuous process, it often requires less power than other manufacturing methods, contributing to energy savings. In an era where sustainability is increasingly important, this efficiency can enhance a company's reputation and meet regulatory standards.

Applications Across Industries

Custom track roll forming machines have a broad range of applications, giving them a vital role across numerous sectors. In the construction industry, for example, they are used to produce components such as framing, supports, and tracks for sliding doors. In the automotive sector, these machines create tracks for various automotive parts, including sunroofs and windows.

The rail industry utilizes custom tracks manufactured through roll forming processes for rail systems, enhancing the quality of infrastructure. Additionally, customized profiles can be created for other applications like HVAC systems, furniture, and recreational vehicles.

Future Trends

As technologies advance, the role of custom track roll forming machines is expected to evolve further. Innovations in materials such as lightweight alloys and advanced composites may open new avenues for roll forming applications. The integration of Industry 4.0 practices, such as predictive maintenance and the Internet of Things (IoT), could enhance the functionality and efficiency of these machines, providing manufacturers with a competitive edge.

Moreover, as global sustainability initiatives become more pronounced, there will be a growing need for manufacturing processes that reduce waste and energy consumption. Custom track roll forming machines, with their focus on efficiency and precision, are well-positioned to play a significant role in meeting these demands.

Conclusion

Custom track roll forming machines represent a crucial advancement in manufacturing technology. Their unique ability to produce high-precision, tailored profiles efficiently offers manufacturers the flexibility and economic benefits necessary to thrive in today's competitive landscape. As industries continue to evolve and adapt to new challenges, these machines will remain integral to the ongoing innovation in manufacturing processes, shaping the future of production across various sectors. Embracing this technology can be a game-changer for businesses aiming to enhance their operational efficiency and product quality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025