Custom Roll Forming Machinery for Tailored Production Solutions and Efficiency

The Evolution and Benefits of Custom Stud Roll Forming Machines

In today’s rapidly evolving manufacturing landscape, the need for flexibility and efficiency drives the innovations in production technologies. One such innovation is the custom stud roll forming machine, an essential tool that enhances the capability to produce high-quality metal studs tailored to specific construction needs. This article delves into the significance, functionality, and benefits of custom stud roll forming machines in modern manufacturing.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically steel or aluminum, is gradually shaped into the desired cross-section. The process involves passing the metal through a series of rollers that progressively alter its shape. The versatility and efficiency of roll forming make it a preferred choice for producing various structural components, particularly in the construction industry.

The Role of Custom Stud Roll Forming Machines

Custom stud roll forming machines are designed to produce metal studs in different sizes, shapes, and thicknesses according to the specifications of a particular project. Unlike standard machines that produce fixed profiles, custom machines can be adjusted to create unique profiles that meet specific design requirements. This adaptability is paramount in today’s construction projects, where custom solutions are increasingly demanded to accommodate diverse architectural designs.

Key Features of Custom Stud Roll Forming Machines

1. High Precision and Consistency Custom stud roll forming machines provide high precision in shaping metal components. They ensure that each stud is uniform in size and strength, meeting the stringent quality standards required in construction.

2. Versatility These machines can produce a wide variety of stud profiles, from simple C-shaped studs to more complex designs. This versatility means that manufacturers can cater to various applications, whether for residential, commercial, or industrial construction.

3. Automation Many custom roll forming machines come equipped with advanced automation features, including computerized controls and sensors. This automation not only streamlines the production process but also reduces labor costs and the potential for human error.

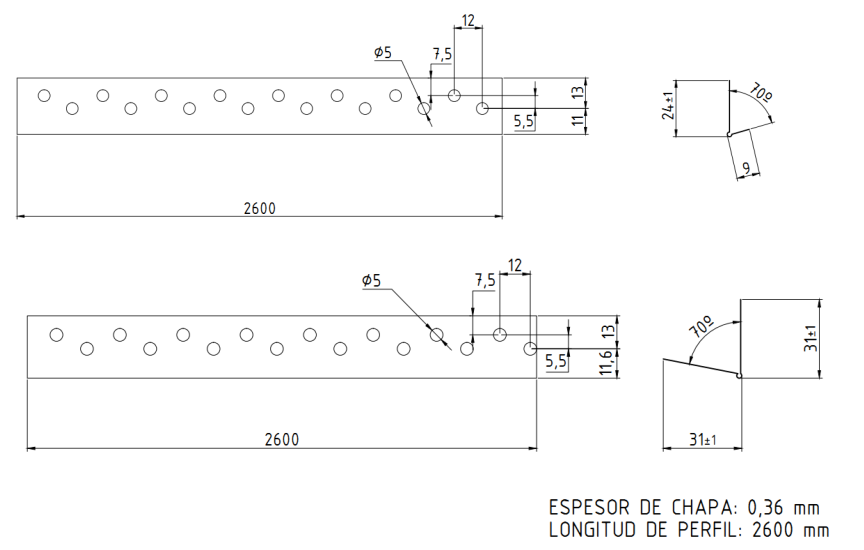

custom stud roll forming machine

4. Material Efficiency The roll forming process is inherently efficient, as it generates minimal waste compared to traditional cutting methods. Custom machines can optimize the use of raw materials, which is beneficial both economically and environmentally.

5. Rapid Production Rates Custom stud roll forming machines can produce components at high speeds, significantly reducing lead times. This efficiency is crucial in construction projects that often operate on tight schedules.

Advantages of Using Custom Stud Roll Forming Machines

The benefits of custom stud roll forming machines extend beyond just the production of metal studs. Some of the key advantages include

- Cost Savings By minimizing material waste and reducing labor costs through automation, manufacturers can achieve significant cost savings. These savings can be passed on to customers, making it an attractive option for builders and contractors.

- Improved Quality With the ability to produce components that meet precise specifications, the overall quality of construction projects can be enhanced. High-quality metal studs contribute to the structural integrity and longevity of buildings.

- Customization The ability to create bespoke components allows architects and builders to bring their unique visions to life. Custom stud roll forming machines enable the production of non-standard dimensions and profiles that may be required for specialized applications.

- Faster Project Turnaround The rapid production capabilities of these machines ensure that construction deadlines can be met, maintaining project schedules and avoiding costly delays.

Conclusion

Custom stud roll forming machines represent a significant advancement in manufacturing technology, offering unique solutions tailored to the demands of the construction industry. Their precision, versatility, and efficiency make them a valuable asset for manufacturers looking to stay competitive in an ever-evolving marketplace. As the construction industry continues to embrace innovative technologies, custom stud roll forming machines are poised to play an integral role in shaping the future of building components and structures. With their ability to provide high-quality, customized solutions, these machines not only enhance production capabilities but also contribute to the overall success of construction projects around the world.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025