custom standing seam roof machine

Custom Standing Seam Roof Machine Revolutionizing Roofing Solutions

In the modern construction landscape, efficiency, durability, and aesthetic appeal are paramount. One of the most innovative developments in roofing technology is the custom standing seam roof machine. This specialized equipment plays a crucial role in manufacturing high-quality metal roofing systems tailored to meet the specific needs of various projects. As the demand for durable and sustainable building materials continues to rise, understanding the capabilities and advantages of a custom standing seam roof machine becomes essential for contractors, builders, and architects.

What is a Standing Seam Roof?

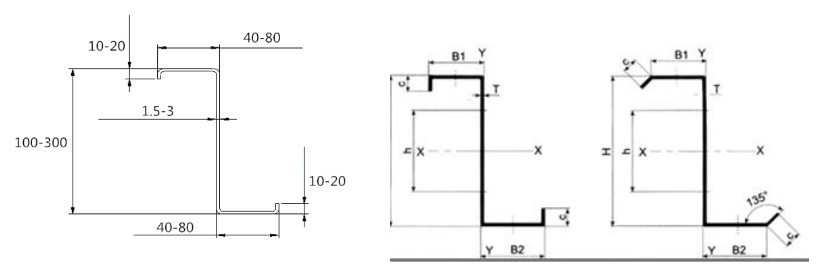

A standing seam roof system consists of metal panels that are interlocked at the seams, creating a distinctive vertical appearance. These seams are raised above the roofing surface, which provides a unique advantage in terms of water drainage and minimizes the risk of leaks. Standing seam roofs are renowned for their durability, long lifespan, and low maintenance requirements. They perform exceptionally well in extreme weather conditions, making them an ideal choice for both residential and commercial buildings.

The Role of Custom Standing Seam Roof Machines

Custom standing seam roof machines are designed to fabricate metal roofing panels on-site or in a factory setting according to precise specifications. These machines can produce panels of varying widths, profiles, and lengths, allowing for tailored solutions that fit the unique dimensions and aesthetic preferences of any project.

1. Precision Manufacturing One of the most significant advantages of using a custom standing seam roof machine is the precision it offers. These machines are equipped with advanced technology that ensures each panel is manufactured to exact specifications. This precision helps minimize waste and ensures a perfect fit during installation, which is critical for long-term performance and aesthetics.

2. Versatility Custom standing seam roof machines can produce a variety of seam types and panel configurations, making them suitable for diverse architectural styles. From traditional to contemporary designs, the flexibility of these machines allows builders to meet the specific aesthetic and functional requirements of different projects.

custom standing seam roof machine

3. Enhanced Efficiency By enabling on-site fabrication, custom standing seam roof machines significantly reduce lead times and transportation costs associated with pre-manufactured panels. Contractors can adapt to project changes quickly, producing the required materials as needed, which boosts overall efficiency.

4. Quality Control Utilizing a custom standing seam roof machine allows contractors to maintain stricter quality control measures. Since panels are made on-site or in a controlled environment, the risk of damage during transportation is minimized, and the quality of the materials can be monitored closely throughout the manufacturing process.

Benefits of Standing Seam Roof Systems

1. Durability Standing seam roofs are typically constructed from high-quality metals, such as steel or aluminum, which provide exceptional strength and longevity. They can withstand harsh weather conditions, including heavy rain, snow, and high winds, making them a reliable choice for many climates.

2. Energy Efficiency Many standing seam roof systems can be equipped with reflective coatings, which help reduce heat absorption and improve energy efficiency. This characteristic can lead to reduced energy costs for heating and cooling, making them an environmentally friendly option.

3. Aesthetic Appeal With a sleek, modern appearance, standing seam roofs enhance the visual appeal of a building. Available in various colors and finishes, these roofs can complement any design scheme, adding to the overall value of the structure.

Conclusion

The introduction of custom standing seam roof machines has revolutionized the roofing industry, providing a solution that combines precision, efficiency, and adaptability. As the demand for high-quality and durable roofing solutions continues to grow, investing in a custom standing seam roof machine allows contractors and builders to meet these challenges head-on. By embracing this advanced technology, the construction community can ensure that they are not only delivering superior roofing systems but also contributing to a more sustainable and efficient building future. Ultimately, custom standing seam roof machines stand as a testament to innovation in construction, offering unmatched quality and value to every project.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025