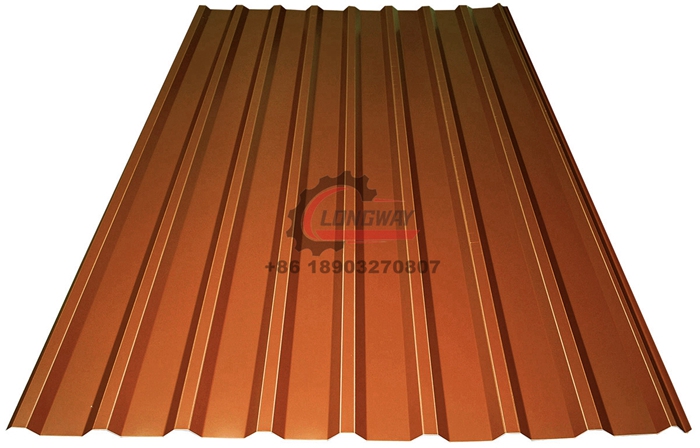

custom standing seam roofing machine

The Advantages of Custom Standing Seam Roofing Machines

In the ever-evolving world of construction, efficiency and innovation have become paramount. One of the significant advancements in this field is the introduction of custom standing seam roofing machines. These specialized machines are designed to fabricate metal roofing panels with a standing seam profile, which has gained popularity due to its durability, energy efficiency, and aesthetic appeal. This article delves into the benefits of these machines and how they revolutionize the roofing industry.

Understanding Standing Seam Roofing

Before diving into the capabilities of custom standing seam roofing machines, it’s essential to understand what standing seam roofing is. This roofing system consists of metal panels with interlocking seams that rise above the level of the roofing surface. The seams are typically secured through a mechanical or snap system, providing superior weather resistance and minimizing potential leaks.

The popularity of standing seam roofing has soared because of its ability to withstand harsh weather conditions. Its design effectively sheds water and snow, preventing accumulation that can lead to leaks or structural damage. Moreover, standing seam roofs are aesthetically versatile, available in various colors and finishes that can complement any architectural style.

The Role of Custom Machines

Custom standing seam roofing machines are specifically engineered to address the unique demands of metal roofing fabrication

. These machines automate the production process, significantly reducing labor costs and increasing productivity. Here are several advantages of implementing custom standing seam roofing machines in construction projects1. Precision Engineering Custom machines are designed to deliver high levels of precision. They can create panels that meet specific measurements and tolerances required for various roofing applications, ensuring a perfect fit that enhances the overall integrity of the roof.

custom standing seam roofing machine

2. Speed and Efficiency Traditional roofing methods can be time-consuming and labor-intensive. Custom standing seam roofing machines streamline the manufacturing process, allowing contractors to produce a large number of panels in a fraction of the time it would take using manual methods. This efficiency translates into shorter project timelines and lower labor costs.

3. Enhanced Product Quality The automation of custom machines reduces the likelihood of human error, ensuring consistent quality in the finished product. High-quality panels lead to stronger and more durable roofs, providing long-lasting protection against the elements.

4. Adaptability The flexibility of custom standing seam roofing machines allows them to produce panels of various lengths and profiles, capable of meeting specific project requirements. This adaptability means that contractors can cater to a wider range of design preferences, further broadening their service offerings.

5. Material Utilization Custom machines often come equipped with features that optimize material use, minimizing waste. Efficient use of raw materials not only reduces costs but also aligns with sustainability practices, an increasingly important factor in today’s construction industry.

Conclusion

The adoption of custom standing seam roofing machines marks a significant turning point in the metal roofing industry. As builders and contractors continue to seek ways to enhance the efficiency and quality of their projects, investments in these machines are proving to be vital. With their ability to deliver precision, speed, and adaptability, custom standing seam roofing machines are not just tools; they are game-changers for contemporary roofing practices.

As the demand for sustainable and durable construction materials grows, the role of advanced technology in roofing will only increase. Custom standing seam roofing machines are set to remain at the forefront, enabling builders to provide high-quality roofs that meet the functional and aesthetic needs of modern architecture. Investing in such technology is an investment in the future of the roofing industry, ensuring that projects are completed efficiently, effectively, and with the highest quality craftsmanship. The integration of these machines into the construction workflow not only benefits contractors but ultimately leads to better-built environments for everyone.

In summary, custom standing seam roofing machines exemplify the intersection of innovation and necessity in modern construction, making them a valuable addition to any roofing contractor’s toolkit.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025