Custom Metal Seam Machine for Precision Standing Seam Applications

Custom Standing Seam Metal Roof Machines A Game Changer in Roofing Technology

In the ever-evolving world of construction and architecture, metal roofing has emerged as a preferred choice for many due to its durability, versatility, and aesthetic appeal. One of the most popular styles of metal roofing is the standing seam roof, characterized by vertical seams that not only provide structural strength but also allow for thermal expansion and contraction of the material. To meet the growing demand for this roofing style, innovation in manufacturing has led to the development of custom standing seam metal roof machines, which have become a game changer in the roofing industry.

Custom standing seam metal roof machines are designed to manufacture metal roof panels on-site, tailored to the specific requirements of each project. These machines offer several advantages over traditional pre-manufactured panels. Firstly, they enable the production of panels in custom lengths and widths, ensuring a perfect fit for any roof design. This level of customization helps minimize waste and reduces the likelihood of leaks, which are often a concern with improperly fitted roofing materials.

Moreover, the use of such machines significantly enhances the speed of installation. Instead of waiting for pre-fabricated panels to be delivered, contractors can produce the panels as needed, which streamlines the construction process. This feature is especially beneficial for large-scale projects where time is of the essence. By reducing wait times and increasing efficiency, custom standing seam metal roof machines allow contractors to complete jobs faster and take on more projects.

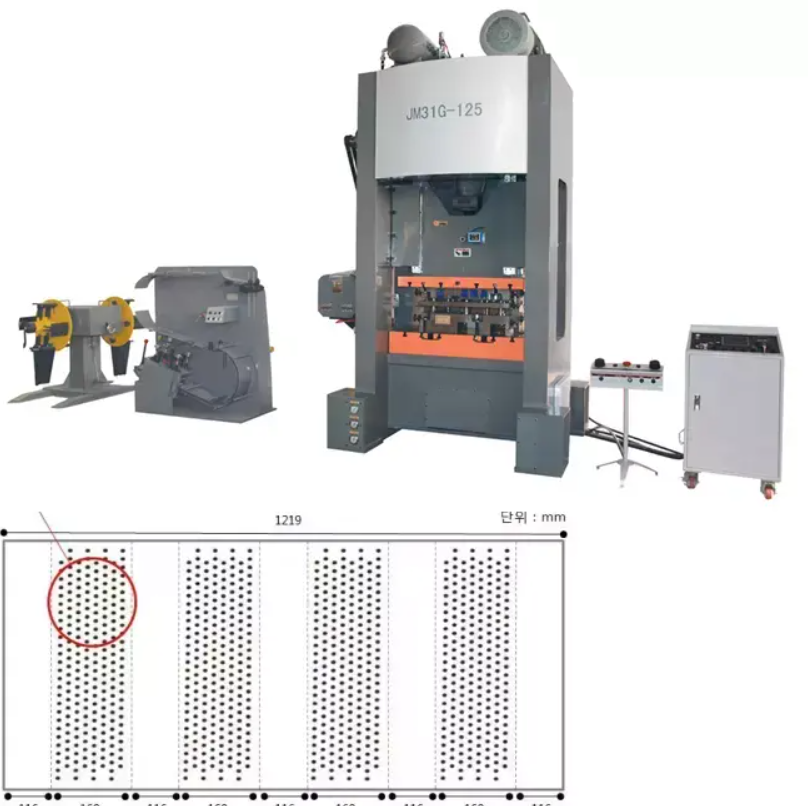

custom standing seam metal machine

The quality of the roofing panels produced by these machines is another critical advantage. Many custom machines employ advanced technology to ensure precise dimensions and consistent thickness across the entire panel. This meticulous attention to detail translates into a higher quality roof that can withstand harsh weather conditions and provide better insulation compared to lesser alternatives. The durability of standing seam roofs made from high-quality materials also means they can last decades with minimal maintenance, making them a wise investment for homeowners and businesses alike.

Furthermore, the use of custom standing seam metal roof machines allows for enhanced design flexibility. Roofing designers can choose from a variety of colors and finishes, matching the metal panels to the overall aesthetic of the building. This customization ensures that the finished product is not only functional but also visually appealing, which can significantly enhance property value.

In addition to their practical benefits, standing seam metal roofs are environmentally friendly. Many metal roofing products are made from recycled materials and are 100% recyclable at the end of their lifespan. This sustainability aspect is appealing to eco-conscious consumers and aligns with the growing trend towards greener construction practices.

In conclusion, custom standing seam metal roof machines are revolutionizing the way roofs are manufactured and installed. Their ability to produce custom panels on-site, enhance installation speed, maintain high quality, and provide aesthetic flexibility makes them an invaluable tool in modern roofing projects. As the construction industry continues to innovate, these machines will undoubtedly play a pivotal role in shaping the future of roofing technology. With their numerous advantages, they offer a compelling reason for contractors and property owners alike to consider standing seam metal roofing for their next construction project.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025