custom standing seam machine price

Understanding the Price of Custom Standing Seam Machines

In the world of metal fabrication and roofing, standing seam machines play a pivotal role in shaping and installing metal roofing systems. These machines have become essential for contractors and manufacturers who seek precision and efficiency in their projects. With the increasing demand for customized roofing solutions, the price of custom standing seam machines has become a significant consideration for businesses. This article aims to explore the factors influencing the pricing of these machines and offer insights into why investing in a custom solution can be beneficial.

What is a Custom Standing Seam Machine?

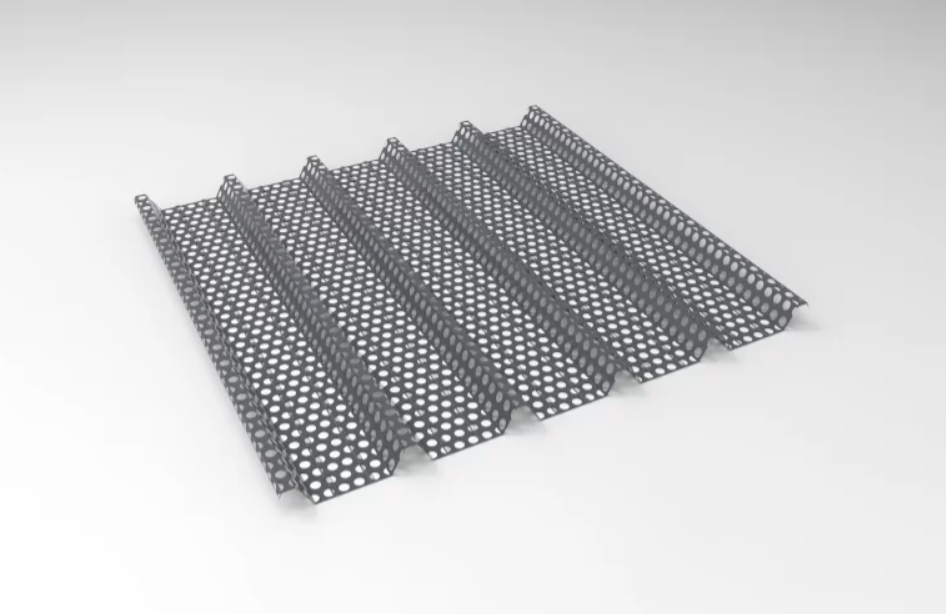

A standing seam machine is a specialized piece of equipment designed to produce standing seam panels, which are widely used in metal roofing applications. These panels have raised interlocking seams that provide durability and water-tightness. Custom standing seam machines can be tailored to meet specific requirements, such as panel widths, lengths, and profiles. This customization allows manufacturers to cater to unique roofing specifications, enhancing their service offerings.

Factors Influencing the Price

1. Customization Level The primary factor influencing the price of a custom standing seam machine is the extent of customization required. Machines with simple configurations are generally more affordable than those engineered for complex designs. Tailored features, such as programmable controls and advanced feeding systems, add to the cost.

2. Machine Specifications High-quality materials and components contribute to the machine's overall functionality and durability. Machines made with robust steel frames, precision cutting tools, and efficient drive systems typically come at a higher price point.

custom standing seam machine price

3. Production Capacity The output capabilities of a standing seam machine can significantly affect its price. Machines designed for high-volume production often have higher costs due to their enhanced engineering and technology. Conversely, entry-level models designed for smaller operations may have a lower upfront investment.

4. Brand Reputation Established manufacturers with a strong reputation in the market may charge premium prices for their machines. Investing in a trusted brand often comes with the assurance of quality, service support, and reliability, making it a worthwhile consideration.

5. Additional Features Advanced features such as digital controls, automatic adjustments for different panel sizes, and integrated safety mechanisms add convenience and efficiency but also increase the overall cost of the machine.

Return on Investment

While the initial purchase price of a custom standing seam machine can be a significant investment, the long-term benefits often outweigh the costs. Custom machines enable businesses to produce unique roofing panels that meet specific client requirements, thereby attracting more projects and potentially increasing revenue. Additionally, the efficiency of a specialized machine can reduce labor costs and production time, further enhancing profitability.

Conclusion

The price of custom standing seam machines varies widely based on several factors, including customization level, specifications, production capacity, and brand reputation. Despite the upfront costs, these machines represent a valuable investment for businesses looking to expand their capabilities and improve efficiency. Understanding the intricacies of pricing can help contractors and manufacturers make informed decisions that align with their business goals. Ultimately, a well-chosen custom standing seam machine can enhance productivity, deliver exceptional product quality, and contribute to greater customer satisfaction in the competitive world of metal roofing.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025